What is a swing hook in a sewing machine?

The shuttle is an important part of any sewing machine, responsible for forming a stitch. It got its name precisely from the original swinging type, by analogy with a boat rocking on the waves.

The shuttle is an important part of any sewing machine, responsible for forming a stitch. It got its name precisely from the original swinging type, by analogy with a boat rocking on the waves.

The content of the article

What is a swinging hook in a sewing machine, its characteristics

The swinging shuttle of a sewing machine performs reciprocating movements during operation according to the principle of a pendulum. Each of these pairs of movements is the creation of another stitch. A bobbin case with a bobbin of lower thread is inserted into the shuttle mechanism. During operation, the shuttle grabs the upper thread that has dropped along with the needle with a special tongue, expands the loop and draws it around the bobbin with the lower thread. The resulting loop is discarded and brought into the next stitch.

ATTENTION! If the thread or fabric is over-tensioned, the looping may become disrupted, causing the thread to wrap around the shuttle mechanism. Under no circumstances should such a breakdown be repaired using brute force. To solve the problem, you need to invite a repair specialist.

This is an old, familiar way of sewing that has been used since the very first sewing machines. It has many advantages, but also many disadvantages, especially when compared with modern modifications of shuttles and sewing units.

The advantages include:

- reliability of parts and the entire structure as a whole: all parts of the structure are made of steel, including the shuttle mechanism;

- the ability to carry out repairs without replacing parts;

- ease of maintenance, accessibility to cleaning and lubrication;

- long service life.

This is true for both mechanical sewing units and electrically driven machines. For home use, when the sewing process is intended solely to meet family needs, swing-type machines are the most suitable option.

The disadvantages include the following:

- limited stitch length, therefore the ability to work only with light fabrics and fabrics of medium thickness;

- low speed;

- high noise level;

- excessive vibration.

The newest types of shuttle mechanisms eliminate these problems, but it is worth keeping in mind that this affects the price of the sewing machine. Oscillating type machines are the most budget option.

What other types of shuttles are there?

Modern types of shuttle mechanisms are divided into horizontal and vertical.

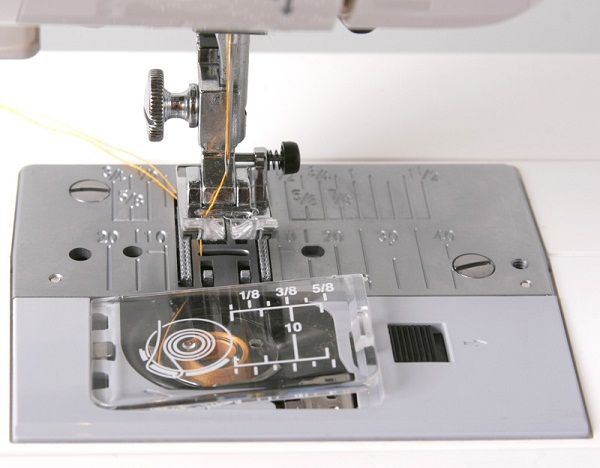

What does horizontal shuttle mean? A similar part is located under a transparent cover in the center of the working field of the machine. In this case, the shuttle mechanism lies horizontally, there is no bobbin case at all, and the bobbin is placed directly into the shuttle. Through the transparent lid you can clearly see the entire process of weaving threads into stitches. Good fixation and adjustment of the shuttle mechanism allows you to work without failures, eliminating the possibility of thread tangling. Machines with a horizontal shuttle mechanism sew quickly and without vibration. Low noise level is another important advantage of such units.But their main advantage is the ability to use any types of fabrics and threads.

There is also one significant drawback of horizontal shuttle type machines. Most of their parts, including the shuttle itself, are made of plastic. Plastic is less resistant to heavy loads than metal. If cracks occur in the plastic, the part cannot be restored and requires replacement.

ATTENTION! It must be remembered that most parts of machines with a horizontal shuttle are made of plastic and do not allow heavy loads. It is better to take care in advance of having a set of spare parts, and above all an additional shuttle in case of failure of a working one.

Vertical shuttle type machines are mainly used in industrial production. The shuttle mechanism in them is powerful and made of metal. Its operation consists of continuous full rotation, allowing it to make significant stitches on fabrics of any density at high working speeds.

In this case, units with a vertical type are divided into several subtypes, determined depending on the method of movement of the mechanism.

Subtypes of vertical type machines:

- with double fitting - the shuttle creates a stitch in two turns: with the first, the thread is removed from the needle, with the second a loop is created;

- rotary - rotate in the same plane with the working shaft of the sewing machine;

- rotating - make circular movements counterclockwise.

In such powerful machines, the connection to the main mechanism is made using special belt drives, which gives additional acceleration to the sewing process.

ATTENTION! The belt mechanism can jump off the supporting tooth and even break if the machine is not operated in accordance with the manufacturer's instructions. Continuous operation of the machine at high speeds must not be allowed; short breaks in operation must be taken.

How to choose the right shuttle

Those who seriously decide to take up sewing do not choose the type of shuttle, but the type of sewing machine as a whole. However, it is best to choose a device if you understand its capabilities, and for this it is still worth focusing on the type of shuttle mechanism.

If the machine will be used rarely and only for household needs, the option of a swinging shuttle device is quite acceptable. Moreover, such a unit is the best budget option.

If a seamstress plans to engage in continuous sewing at home or open her own atelier and carry out complex orders from different types of fabrics, it is better to focus on units with a horizontal shuttle mechanism. This option is more expensive, but speed and variety of features are important factors in favor of choosing it.

When using an industrial sewing machine, the most correct choice is a vertical shuttle device.