DIY cyclone filter for vacuum cleaner

During construction work, large amounts of dust accumulate in the premises being renovated. It contains substances harmful to breathing and must be cleaned regularly. Conventional household vacuum cleaners are not designed for cleaning construction waste and concrete dust, because, firstly, they have an insufficient waste container size, and secondly, their filters clog very quickly, which can lead to overheating and breakdown of the device.

During construction work, large amounts of dust accumulate in the premises being renovated. It contains substances harmful to breathing and must be cleaned regularly. Conventional household vacuum cleaners are not designed for cleaning construction waste and concrete dust, because, firstly, they have an insufficient waste container size, and secondly, their filters clog very quickly, which can lead to overheating and breakdown of the device.

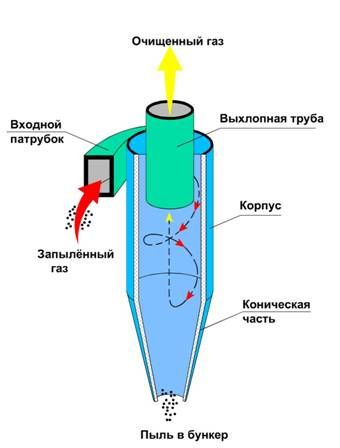

In this case, a cyclone filter will help, which will allow you to expand the debris compartment and adapt the filtration system due to the primary capture of the main part of the dust inside the separator.

The advantage of a cyclone filter made by yourself is that the installation price is significantly lower than when purchasing an industrial household appliance; it can be made of any shape, power and volume at minimal cost. Disadvantages include lower energy efficiency and dust removal quality.

The content of the article

Materials

To make your own cyclone filter, you will need the following consumables:

- a classic vacuum cleaner or donor device from which the motor will be removed;

- trash container (optionally, a bucket or barrel);

- conical container (or cyclone);

- corrugated hoses;

- plumbing fittings with transition seals;

- fastening hardware;

- sealant;

- plywood (chipboard, etc.).

Depending on the assembly option, other components may be needed.

Now let's look at the options for how to assemble a cyclonic model of a vacuum cleaner.

Step-by-step production of a cyclonic vacuum cleaner with your own hands

Depending on the chosen path, the sequence of work may differ slightly. First, let's look at the simplest option.

From a home vacuum cleaner

Besides the old one vacuum cleaner The cyclone purchased assembled will be used as the second main component.

To begin, make two hoses: one is a working hose with a cleaning nozzle, the second is an intermediate hose to connect the cyclone to the device. Cut corrugated tubes of a suitable diameter, secure plumbing bends to the ends on both sides through adapter couplings treated with sealant.

During operation, the cyclone will dump garbage into a container located underneath it. As the latter, you can use a bucket with a lid. A hole is made in the cover to match the diameter of the cyclone outlet, after which the two parts are aligned and attached to each other through the holes provided by the cyclone design.

If necessary, you need to strengthen the structure of the bucket around the perimeter in any available way to avoid its deformation under the influence of vacuum. Now all that remains is to connect all the holes using the previously made sleeves. The nozzle is installed on the working hose - the device is ready for use.

From the bucket

If you don’t have a working vacuum cleaner, you can make one yourself.In this case, it is necessary to assemble a sealed housing from available materials, for example, from chipboard, and install a motor in it. It is necessary to electrically connect the motor terminals to the power button through the power regulator.

The wires of the power cord are soldered to the remaining terminals of the button. It is worth noting that the motor, power control unit and other electrical components can be used from an old vacuum cleaner that has lost its functionality. All electrical connections must be properly insulated and protected from dust.

The second cascade of the system will be a cyclone - it can be manufactured from a bucket conical shape. The main task is to organize the inlet hole so that it is directed downwards tangentially to the inner wall.

This is necessary so that a cyclone is formed in the container, which will force the garbage to fall under its own weight into the container, and the trapped air will be removed through the outlet hole in the lid of the bucket. It is necessary to lower the plumbing pipe connected to the air intake compartment into it to a height below the inlet.

The lowest cascade is a garbage container. An improvised cyclone with a motor on top will be installed on it. It can also be done from a bucket with a hermetically sealed lid. This compartment must be the most durable, because in addition to the mass of the entire structure, it also needs to withstand the resulting vacuum.

After connecting all three cascades with hoses and removing the “exhaust”, you can begin testing. A vacuum cleaner assembled by yourself has a big disadvantage - it will not be able to hold fine dust, being effective only for large construction waste.

From a traffic cone

As a filter, instead of a ready-made cyclone or bucket, you can use a construction cone. Its shape is also quite suitable for generating the necessary air flows for effective dust retention. The sequence of actions is the same:

- turn the cone upside down;

- in the side of the cone, closer to the base, a hole is made tangential to its inner surface;

- the outlet pipe is lowered from above, which should end below the inlet - it is secured by means of a plywood disk cut to the size of the base of the cone;

- The top of the inverted cone is cut off and it is secured to the lid of a waste container - a large bucket or barrel, also using a round piece of plywood.

The upper pipe is connected to the vacuum cleaner, the second pipe is threaded with a hose with a working nozzle. Assembly is complete.

Conclusion

When making a cyclone filter yourself, you may encounter the following difficulties:

- The difficulty of attaching the inlet pipe to a homemade cyclone. It is very important to organize the correct air movement at the inlet of the filter. To do this, it is recommended to use plumbing bends at an angle of 870 or 600;

- Insufficiently sealed assembly. During the manufacture of the unit, it is necessary to ensure the tightness of structures and connections along the entire route of air flow. Do not skimp on sealant for processing joints and joints;

The containers of the device, especially the waste container, may be subject to deformation under the influence of vacuum. Strengthen the design of the relevant parts (barrels or buckets), carefully select the device’s motor according to power, preferably with the ability to adjust it;

The containers of the device, especially the waste container, may be subject to deformation under the influence of vacuum. Strengthen the design of the relevant parts (barrels or buckets), carefully select the device’s motor according to power, preferably with the ability to adjust it;- Also, issues of attaching parts and assemblies of a hybrid vacuum cleaner may cause some difficulty. The structure must be rigid, well fixed and durable, in order to avoid its destruction during operation of the device. Since the unit is often large and heavy, it is advisable to mount it on a small platform with wheels.