Working principle of a knitting machine

Knitting is a great way to provide yourself and your loved ones with warm and exclusive wardrobe items. For some, this activity is very difficult and time-consuming. This is what led to the creation of such a device as a knitting machine. Many needlewomen are frightened by its scary appearance and, at first glance, complex design. But if you look into it a little, everything turns out to be simple and clear, and the knitting process becomes fast and tireless. And if desired, it can turn into an additional way of earning money.

Knitting is a great way to provide yourself and your loved ones with warm and exclusive wardrobe items. For some, this activity is very difficult and time-consuming. This is what led to the creation of such a device as a knitting machine. Many needlewomen are frightened by its scary appearance and, at first glance, complex design. But if you look into it a little, everything turns out to be simple and clear, and the knitting process becomes fast and tireless. And if desired, it can turn into an additional way of earning money.

The content of the article

What is a knitting machine

A knitting machine is a device that allows you to easily and quickly produce knitted products with a variety of patterns. It makes it possible to obtain material with various color patterns. By purchasing such a machine, you will be able to create unusual things for all family members and more. But first you will need to figure out how to work with it.

Unlike hand knitting, this tool will produce smoother fabric. Among the main advantages of this device:

- speed of work;

- smooth and dense rows of loops;

- the ability to easily make any openwork pattern.

REFERENCE! It should be noted that there is a large selection of these devices on the market. This makes it possible to choose a machine class that allows you to knit from yarn of various thicknesses.

Knitting machine design

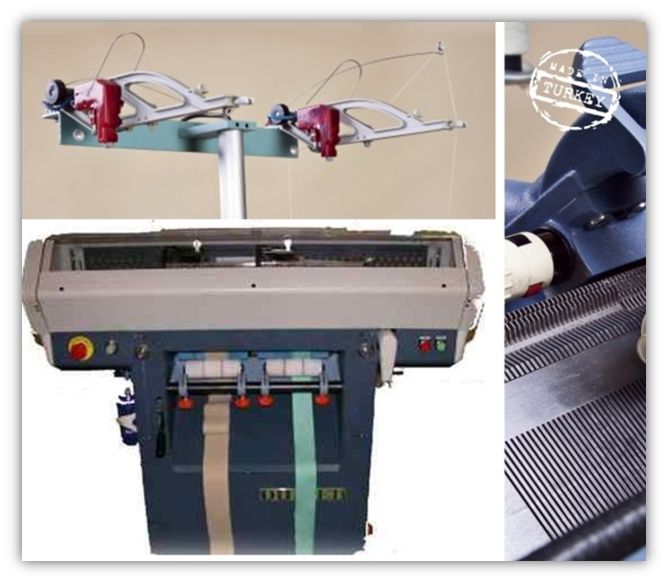

This device has many needles on which the fabric is formed. This is what makes it so productive. The carriage acts as a second knitting needle and makes loops. True, such a device makes the machine very large and “demanding” of the workspace.

Once you understand what parts this mechanism consists of, it will be easier for you to understand the principles of creating fabric in it and begin to work effectively. The main elements of the device are:

- Fontoura. This is the basis of the mechanism. Knitted needles are attached to it; its other name is a needle bed.

- Punch card or computer. Attached to the font from above. This is where the canvas pattern is adjusted.

- Needles. They are fastened in a long row in a needle bed. Participate in the formation of loops. Most cars have about 200 of them.

- Carriage. Main mechanism. Moves freely along a row of needles and serves to form loops. The carriage has a knitting density regulator in the form of a disk.

There are single and double font machines. They differ in functionality and the number of available knitting patterns. There are also a large number of different accessories for knitting machines that will simplify your work and provide new opportunities.

Working principle of a knitting machine

Knowing the purpose of all the parts of this unit and its operating principles will make the knitting process easy and fast. The main design element is the needles. It is on them that the canvas will be formed. The needles have four working positions, which are marked on the outline with the following symbols:

- ZNP (posterior non-working position). The heels of the needles are pushed back all the way to the rear rail.

- PNP (anterior non-working position). The needles are pushed forward all the way.

- RP (working position).Used for knitting even fabric.

- FRP (front working position). It knits various patterns.

ATTENTION! In different models, the markings may differ, for example, they may be: A B, C, D. For clarification, it is better to refer to the instructions for your model.

The machine carriage is designed to create new loops. She does the main work here. This part has a material density regulator at the outlet. Work on this unit is carried out by moving the carriage along the needles on which the yarn is put. In this case, a new row of loops is formed and a web is produced. The pattern depends on the position of the needles and the presence of thread on them.

Types of knitting machines

There are several types of knitting machines, differing in their capabilities and purpose. Household items mainly have a single-strip knitting system, which leads to the need for additional seams. Depending on the number of needle beds, the devices are:

- Single-font. The simplest and most common option. Has the ability to knit a small number of different patterns, but is not able to make a circular fabric.

- Double-font. A more advanced and professional copy. It is more difficult to operate and more expensive, but it provides many additional functions. These include knitting a large number of ornaments and the ability to make colored patterns.

The devices also differ in the way they control the needles. They can be either manual or with punch card or computer control. Electronic systems allow you to customize the desired design and easily translate it onto the canvas. Punch cards allow you to do the same thing, but to select a different pattern you will have to buy the corresponding plate. You can also make them yourself by punching the required holes in the plastic cards intended for this purpose with a special punch.

Classes of knitting units

These devices are classified according to the distance between the spokes. The density of the finished fabric and the thickness of the yarn that can be used depend on this. The third grade has a spacing of 9mm and is good for thick thread. The tenth is 2.8 mm, it is suitable for the finest yarn.

Although the knitting machine looks “intimidating”, it is not difficult to operate. By spending a little time mastering it, you can give yourself and your family unique items of clothing. At the same time, without spending as much time as with hand knitting.