DIY polypropylene heated towel rail

An indispensable accessory in Russian bathrooms is a heated towel rail. It is indispensable not only for drying clothes, but also for maintaining a dry microclimate, which prevents the appearance of mold and mildew. The most budget option is a self-assembled structure made from polypropylene pipes.

It is quite simple to manufacture, but for beginners there is a risk of incorrect assembly, connection and unreliable pipe connections.

ATTENTION! It is not recommended for beginners without experience in plumbing to start working, in particular with polypropylene pipes, since in the event of an accident the room will be flooded with boiling water!

The content of the article

Preparation of materials and tools

First of all, it is worth determining the type and size of the future dryer. By type of construction we can distinguish:

First of all, it is worth determining the type and size of the future dryer. By type of construction we can distinguish:

- Vertical (“Ladder”);

- Horizontal (“Snake”) products.

ADVICE! It is worth planning the simplest design with a minimum number of connecting elements in order to reduce the likelihood of leakage and increase the service life of the product.

IMPORTANT! It is necessary to take into account the operating pressure of the hot water supply. There is a high probability of an accident due to too high a temperature or pressure changes! Before work, check the characteristics of your home’s system!

According to the principle of operation, our product can be divided into:

- Aquatic - i.e.mounted in a heating system or hot water (a more economical option, but depending on the heating season);

- Electric (increase electricity consumption);

- Combined (combine the characteristics of the previous two types).

Having decided on the size and type of structure, we need to prepare everything in advance. So, to install and manufacture a polypropylene dryer we will need:

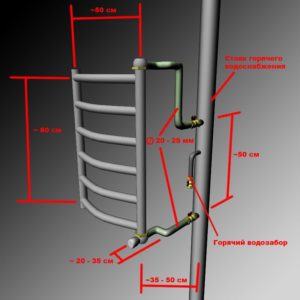

- The polypropylene pipes themselves, from which we will assemble our dryer (It is worth considering the size of the coil. It must match the seats of your wiring. As a rule, the most acceptable diameter is 20 +/- 5 millimeters);

- Brackets or fastenings for mounting the device;

- Polypropylene couplings;

- Two or three ball valves. More is better;

- Welding machine for polypropylene pipes;

- Knife for cutting pipes;

- (In case you chose an electronic or combined option) Heating elements (110 W) with an external thread of 0.5 inches + circuit.

Nuances of assembly

Before assembling a polypropylene heated towel rail with our own hands, we need to create our own pipe configuration. It is worth considering that the weakest part of the structure is its connecting nodes. The slightest mistake when installing compression fittings will lead to an accident! It is not recommended to start working without experience with a soldering iron for polypropylene!

Before assembling a polypropylene heated towel rail with our own hands, we need to create our own pipe configuration. It is worth considering that the weakest part of the structure is its connecting nodes. The slightest mistake when installing compression fittings will lead to an accident! It is not recommended to start working without experience with a soldering iron for polypropylene!

ADVICE! Before assembly, draw the structure you want to assemble! You need to consider the size of the bathroom.

The drawing should also take into account the type of connection of the dryer. He can be:

- Lateral/Diagonal with top feed. (In this case, the diameters of the pipe and nodes must match. The narrowing will lead to improper operation of the system or even an accident. This method is based on the principle of natural circulation);

- Lower. Combining natural and forced circulation of hot water. This method requires the presence of a “Maevsky tap”, which is necessary to combat air jams.

Attention! When installing the product, the lower outlet must be located above the outlet point, and the upper outlet, accordingly, below the connection point.

Most often, the Mayevsky crane cannot be installed on such systems. An ordinary screw that needs to be screwed into the corner docking unit can help you. It allows you to release the accumulated air lock.

However, please note that this solution is not a panacea. Over time, a leak may appear in this area. This method also increases the risk of a breakthrough.

Features of connecting a heated towel rail made of polypropylene

So. Having taken into account all the subtleties and moments, we proceed to assembly:

So. Having taken into account all the subtleties and moments, we proceed to assembly:

- Turn off the water.

- We will dismantle the old dryer if necessary.

- Connect the Jumper/Bypass. This will serve.

- We install ball valves. This will help remove excess air, which will have a positive effect on the circulation of boiling water.

- We prepare and weld pipes using a special apparatus (You can either buy it or rent it).

- Let's start installing our product. Do not forget to maintain the distance - If the pipe diameter is less than 23 mm, the distance to the wall should be no more than 35 mm, if more than 23, then no more than 50 mm.

- We check all connections for tightness and reliability.

- We turn on the water.

Great! You have successfully installed a polypropylene heated towel rail!