Why doesn't a drill drill into concrete?

Concrete is called artificial stone for its high strength. Particularly difficult for drilling is heavy concrete, which contains coarse natural filler - crushed stone or gravel.

Concrete is called artificial stone for its high strength. Particularly difficult for drilling is heavy concrete, which contains coarse natural filler - crushed stone or gravel.

The content of the article

Why the drill does not drill concrete: reasons

It was from concrete that the structures were made, which were the basis for the construction of panel houses built by Khrushchev. These houses remain the main type of housing in many Russian cities today.

Modern multi-storey buildings are built primarily using monolithic frame technology, when first a reinforcing frame of the building is created, which is then filled with the same heavy concrete. It also includes: fine filler – sand, binder – cement and water. The strength of the material depends on the quality of all components and the amount of cement.

Reference! A feature of concrete is a rapid increase in strength within 28 days, and then a slow increase over a number of years.

Therefore, almost all city residents face the problem of drilling holes in concrete.

What kind of drill should it be?

For drilling holes in concrete, the best tool is a hammer drill, which was designed to work with particularly durable surfaces. It has increased power compared to a conventional drill and a hammer function, which makes work easier. The maximum hole diameter is 120 mm.

Attention! To work with lightweight cellular concrete with a porous structure, you should use a hammerless drill or screwdriver.

When drilling small-diameter holes with a depth of up to 10-12 mm, you can use an impact drill, which can easily cope with this task. In non-impact models, when working with concrete, the cartridge and nozzle very quickly become unusable. The maximum hole diameter when working with a drill is 13 mm.

In addition to hammer drills, in professional construction, for large-diameter holes in walls of considerable thickness, drills with diamond core bits, equipped with a water cooling system and a clamping device, are used. The resulting holes are of ideal quality, and all the debris is a cut out concrete cylinder. This expensive option is not practical for home use.

How to choose the right drill

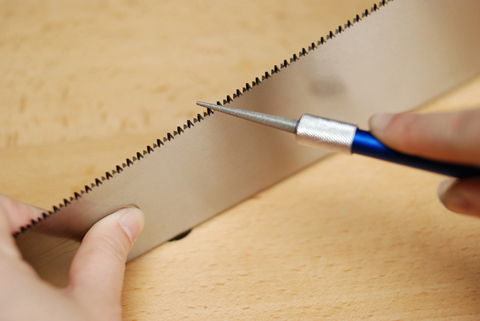

For effective work, you must choose the right drill. Normally, when it gets on crushed stone or reinforcement, it instantly becomes dull.

Drills suitable for concrete structures:

- With a pobedit tip - the most budget-friendly and popular option for household use. Works provided there is a shock function. They have an SDS tail for installation in a drill with a keyless chuck. When working with porcelain stoneware, pobedit tips become dull after drilling 1-2 holes.

- Diamond coated is the best option. They can work without a shock function, the cost is an order of magnitude higher than the Pobedit ones. More often used by professional craftsmen when a large number of holes are needed.

Diamond crowns are circular bits for large diameter holes of 10-120 mm, for example, for a socket or pipe.To work with a hammer drill or impact drill, you must choose a diamond bit with a centering drill, which will prevent it from slipping. The edge of the crowns has an abrasive structure.

Reference! A special feature of diamond crowns is that they can drill reinforced concrete without affecting the integrity of the crown when it encounters reinforcement.

Tungsten bits are identical in design to diamond bits, but with a more modest cost. Suitable also for concrete walls.

How to prepare the surface before work

First, you need to clearly define and mark with a construction pencil or a small recess (drilling it slowly in a non-stress mode) the location of the future hole. A small recess makes it easier to start working, preventing the nozzle from slipping.

Important! You should first make sure that no electrical cables, water supply, sewerage or heating pipes pass within the drill’s operating range.

After checking the condition of the hammer drill and the integrity of the nozzle, perform the following operations:

- Place the drill in the chuck until it clicks.

- Bring the hammer drill perpendicular to the wall and begin to carefully drill at low speeds, lightly pressing on the tool.

- Gradually increase the speed and switch to shock mode. For low-power equipment, the operating time should not exceed 10-12 minutes. During long-term operation, the drill should be periodically wetted in water to avoid its deformation, and the motor should be protected from overheating, taking breaks to cool it.

- A stuck drill bit can be pulled out using a smaller diameter bit, increasing the diameter of the hole around the stuck tip.

Concrete dust resulting from drilling can be easily collected with a vacuum cleaner.