How to brew a cast iron stove on a stove

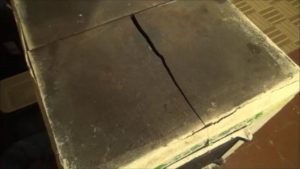

In the old days, cast iron was very often used for stove plates. When cracks appeared on it, you could simply throw them away and put another one in its place - a new one. But with the development of technology, stoves began to be thrown out of the house, and cast iron stoves, which were not in demand, became a shortage on the market. Therefore, those few people who have cast iron left on the stove are wondering: how to weld cracks?

In the old days, cast iron was very often used for stove plates. When cracks appeared on it, you could simply throw them away and put another one in its place - a new one. But with the development of technology, stoves began to be thrown out of the house, and cast iron stoves, which were not in demand, became a shortage on the market. Therefore, those few people who have cast iron left on the stove are wondering: how to weld cracks?

The content of the article

How to brew a cast iron stove

There are many ways to weld cast iron in general, these are inverter, cold welding, hot welding, semi-hot.

Preparing the Slab

Preparation of cast iron before the welding process is mandatory. For cleaning, a grinder with a petal circle is used. As soon as the rust layer is removed, you need to treat the slab with a degreasing solvent. During the preparation process, you need to pay attention to:

- Stiletto heels. There are two types of welding, with and without support elements.

- Cutting edges.

- Using special electrodes.

Selecting a brewing method

There are only three methods for welding cast iron:

- Hot. It is considered the main and most suitable for this type of material. The essence of welding is that before you start working with electrodes, you need to heat the metal to a high temperature.

- Semi-hot. This method is identical to the previous one, except for the heating temperature, which should be lower.

- Cold.Characterized by a large number of technological processes, but does not involve heating.

Brewing a cast iron stove: step-by-step instructions

Before you start welding cast iron at home, you need to properly prepare the metal and follow the step-by-step instructions:

- Edge cutting is carried out at 450, if the slab plate is thick. This procedure can be carried out using a grinder or a sharpening machine. A crack in cast iron is initially treated with an abrasive disc, and then the ends of the defective area are drilled.

- The graphite base is placed under thin material (3mm). Molten metal will not flow from the reverse side during welding.

- The metal must be cleaned of dust, rust and debris. After this, it must be heated using a blowtorch or other equipment.

- The welding process begins as soon as the required temperature is reached. The sides of the slab must be secured using tacks.

- It is not recommended to allow transverse vibrations during the first weld; it is carried out very quickly. The seam is adjusted from several sides if the length of the slab exceeds 100 mm. This procedure will help avoid overheating the cast iron on one side.

- If the plate is thick, then it is necessary to make the seam in several moves. For better adhesion of cast iron, after the first smooth seam, oscillatory ones are made.

- After each seam, slag is separated.

Important! As soon as the welding process is completed, the seam must be covered with sand until the product cools completely.

The process of welding such metal at home using an inverter is very successful.

Yes, you don’t need to bother too much. Drill holes, cut threads and fasten them with plates... Welding there with borax... everything will burst, I know from experience, but I twisted the plates on that side and that’s it...

So what electrodes?

How complicated everything is!! How many body movements? Smart guys. Stainless steel electrode 3.25 and current 90-125 A, and the stove will fall apart forward.

It is not very clear why to degrease parts before WELDING.

Maybe they still need to be primed? )))