Gas control in a gas stove - what is it?

Despite the popularity of gas stoves due to their simplicity, efficiency, and excellent cooking performance, many still neglect to purchase and install them due to safety, having heard and read about numerous accidents associated with gas stoves. Nevertheless, the development of technology does not stand still: it becomes better, higher quality and safer every year, including gas stoves. One of the introduced safety systems was gas control, which is now installed in almost all models and controls the gas supply.

The content of the article

Gas control in a gas stove - what is it?

Many, seeing gas control stoves in the passport, wonder what it is, what additional function it is, and whether it is worth paying for it. Gas control is a safety system that prevents gas leaks, allowing you to protect against the risk of fire or explosion, which can cause death or significant damage. In essence, gas control is a device that stops the gas supply if the flame goes out for any reason.

Many, seeing gas control stoves in the passport, wonder what it is, what additional function it is, and whether it is worth paying for it. Gas control is a safety system that prevents gas leaks, allowing you to protect against the risk of fire or explosion, which can cause death or significant damage. In essence, gas control is a device that stops the gas supply if the flame goes out for any reason.

In the first models (this still remains in some older variations), gas control was installed on the entire stove.Now each burner, as well as the oven, is equipped with its own sensor, which allows you to selectively prevent the supply of gas to various elements of the oven, rather than depriving the entire stove of gas at once. Using this feature, you can leave the oven unattended while cooking without worrying about dangerous situations occurring or abruptly stopping all food cooking.

Important: gas control relieves the user of the need to closely monitor cooking, but does not allow the user to leave this process unattended for a long time, much less leave the apartment with the stove running.

How does gas control work on gas stoves?

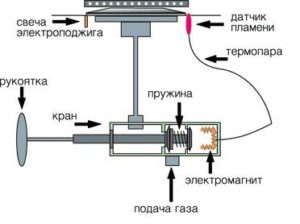

Gas control, regardless of whether it is supplied to the entire slab or to its individual elements, does not differ significantly in its design. It includes the following components:

- thermocouple;

- solenoid valve.

A thermocouple is a connection of wires made of two different metals. They are fused to each other at one end, which looks like a small, smooth ball. When it heats up, a thermopower arises, which is then converted into an electrical signal and transmitted to the solenoid valve, thereby opening the valve, which creates pressure on the burner tap and gas begins to flow.

If the fire dies out, the thermocouple loses its temperature, which is why the electrical signal first weakens and then completely fades out. The solenoid valve can remain open only if there is a signal, so after it disappears it closes and the gas supply is accordingly stopped.

If we abstract from the technical principle of operation and move on to the everyday one, then everything seems to be a combination of the following actions:

- You need to press the button or turn the knob with pressure (all depending on the method of implementing gas control) - this will open the gas supply.

- Light the fire using automatic ignition or matches, holding the gas control button pressed. It takes a few minutes for the thermocouple to warm up, after which the button can be released. If you do this earlier, the gas will go out, since a sufficient signal still reaches the solenoid valve, allowing it to remain open.

Help: most gas control systems allow you to relight the burner without holding time for warming up, if only a few seconds have passed after the flame has gone out and the thermocouple has not yet had time to cool down.

Advantages and disadvantages that characterize this system

Like any technical element, the gas control system has its advantages and disadvantages. The first ones, as a rule, border on its functions and boil down to the fact that gas control allows you to:

- automatic shutdown of gas supply when the flame on the burner or in the oven goes out;

- getting rid of constant monitoring of the furnace during its operation;

- prevention of dangerous situations associated with fires and explosions.

No one has rid gas control of its shortcomings. Inventors are working to eliminate them, but for now they still exist. These usually include:

- the need to hold a knob or button pressed while waiting for the thermocouple to warm up and transmit a signal to the solenoid valve;

- lack of stable operation of burners and ovens in case of system failure;

- difficult repairs (especially if you decide to do it yourself and do not have similar work skills).

Due to these shortcomings of the gas control system, many users resort to turning it off. To achieve this goal, you must adhere to the following algorithm of actions:

- turn off the gas supply from the gas pipeline;

- find where the gas control system is located in your case (its location is different in all models);

- disconnect and remove the solenoid valve;

- pull out the spring, which is responsible for the flow and shutoff of gas;

- return the solenoid valve to its place.

Removing the spring is precisely responsible for freeing the stove from automatic restrictions on the gas supply. In this case, the valve will always be open, regardless of whether it receives a signal from the thermocouple or not.

Disabling gas control will not be difficult, however, any independent operations with gas household appliances can lead to an accident, so for such work it is best to call a specialized technician.

Important: in some cases, for turning off gas control yourself, the gas company may impose a fine on you or completely stop supplying gas due to violation of the terms of the contract.

When the technician turns off the system, at the end of the work he makes appropriate notes in the device operation log indicating the date and reason for the action (very often the gas control is turned off when leaving the system, so as not to waste money, time and effort on repairing it).

Gas control stops functioning properly in the following cases:

- when the sensor elements are heavily contaminated;

- when the thermocouple is displaced (its rounded end should always be on the border with the flame);

- thermocouple obsolescence;

- solenoid valve wear;

- weakening the connection of elements.

Repairs related to the replacement of elements are best left to a specialized organization in order to protect yourself and avoid problems with the law. You can clean the thermocouple of contaminants or tighten the connections yourself.

thanks for the info