Do-it-yourself ovens

The specificity of heating non-residential premises is lower requirements for the climate in these premises. This may be a reduced amount of oxygen, unacceptable for residential premises, and an increased amount of carbon dioxide and other waste gases. As a result of these requirements, the owners of such premises try to save on the cost of heating, which is quite expensive in today's world. Such premises may include garages, warehouses, repair shops and much more.

The content of the article

How the device works

Standard or generally accepted types of fuel in such premises are considered quite expensive and the owners are trying to use a cheaper fuel option. One of these options is the processing of technical oil. This can be motor, transmission or transformer oil.

Standard or generally accepted types of fuel in such premises are considered quite expensive and the owners are trying to use a cheaper fuel option. One of these options is the processing of technical oil. This can be motor, transmission or transformer oil.

Important. Whatever oil is chosen, in any case, it must be purified, not only from mechanical impurities, but also from chemical ones, and this is what can become a problem at home.

So, let's figure out what working out is. This is oil that has completed its task when working inside the engine or other elements of a car or tractor. Processing in large industries is an unaccounted by-product that can be given away for free or for a small reward.

From the point of view of chemical composition, this is a carbon compound obtained after processing oil to obtain lighter fractions, such as gasoline or diesel fuel. And it has a good ability not only to burn but also to generate heat.

Do-it-yourself oil furnaces have the following advantages:

- Simplicity of design;

- Inexpensive fuel;

- Large reserves of this fuel are especially present in large enterprises.

The disadvantages of stoves include:

- The presence of an open fire, which means a lack of oxygen in the room.

- Lack of burning rate control systems or they are very expensive.

- It is not easy to set up the system for complete combustion of fuel.

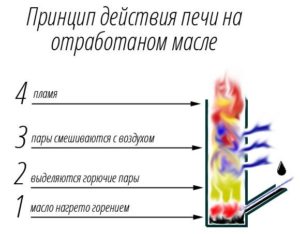

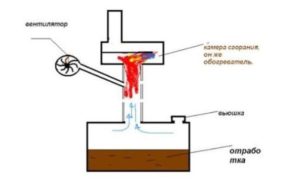

The mining stove is designed in such a way that it contains two combustion chambers. In the first chamber, the used oil burns directly, releasing a wide variety of gases heated to high temperatures. A portion of oxygen from the air is mixed into these gases and this mixture enters chamber two, where the final combustion of this mixture occurs and a large amount of heat is released.

Drawing for creating a furnace for testing with your own hands

There are a large number of original designs for waste oil stoves on the Internet. All these developments are put on public display and their authors are not only ready to share the secrets of their developments, but are also ready to help readers who would like to assemble such a stove with their own hands. There are quite a lot of photographs of working stoves on websites on the Internet, and many even have videos of their operation.

There are a large number of original designs for waste oil stoves on the Internet. All these developments are put on public display and their authors are not only ready to share the secrets of their developments, but are also ready to help readers who would like to assemble such a stove with their own hands. There are quite a lot of photographs of working stoves on websites on the Internet, and many even have videos of their operation.

Most often, such stoves are made from auxiliary materials, of which there are quite a lot in garages and personal plots. For the manufacture of stoves, sheet iron with a thickness of more than 4 mm is often used.Or, as many craftsmen have noticed, a used gas cylinder is suitable.

Getting the remaining structural elements is not difficult and requires a minimal set of plumbing tools.

Assembling the device

According to reviews from owners of existing stoves, assembling such a device is not difficult. This job does not require particularly precise parts. Step-by-step instructions for assembling and setting up a waste oil furnace are also easy to find on the Internet.

According to reviews from owners of existing stoves, assembling such a device is not difficult. This job does not require particularly precise parts. Step-by-step instructions for assembling and setting up a waste oil furnace are also easy to find on the Internet.

Important to remember! Before starting commissioning work, it is important to carefully check the quality of the stove assembly and the absence of fuel leaks.

You can save on heating non-residential premises, but you don’t need to invest a lot of money in this matter. Using auxiliary materials, it is possible to manufacture and install a compact waste oil stove and heat non-residential premises.