Reasons for lack of draft in the furnace

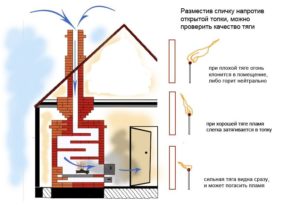

Heating a country house in winter is determined by the correct operation of the boiler or furnace. The absence of a burning smell from smoldering wood in the firebox confirms the presence of good draft. And the constant aroma of a fire in the house indicates possible malfunctions of the stove equipment.

Heating a country house in winter is determined by the correct operation of the boiler or furnace. The absence of a burning smell from smoldering wood in the firebox confirms the presence of good draft. And the constant aroma of a fire in the house indicates possible malfunctions of the stove equipment.

The content of the article

Why is there no draft in the furnace?

If an unpleasant odor is detected, it is necessary to eliminate the reasons for the deterioration of the exhaust gas removal system. To identify the factor influencing traction, it is important to consider the nature of the malfunction. If the smell appeared from the beginning of the stove’s operation, then the reason may lie in the design or features of the chimney. If a smoke aroma suddenly appears, the origin of the defect may be caused by external factors.

Causes related to the stove

The presence of poor draft from the first day of operation of the stove indicates that the internal structure of the chimney openings or structure does not allow exhaust gases to be removed from the furnace outside naturally. It is no coincidence that since ancient times, in small villages there were craftsmen who knew how to lay out a stove correctly and passed on the knowledge by inheritance.

The presence of poor draft from the first day of operation of the stove indicates that the internal structure of the chimney openings or structure does not allow exhaust gases to be removed from the furnace outside naturally. It is no coincidence that since ancient times, in small villages there were craftsmen who knew how to lay out a stove correctly and passed on the knowledge by inheritance.

REFERENCE! To correctly calculate the cross-sectional dimensions and length, experts use the unit of measurement Pa (Pascal), which shows the rarefaction of air by natural draft when the height of the chimney changes.Based on the value of this indicator, stove makers choose the complexity of the internal structure of the stove.

Let us consider in detail the design features that affect traction:

- The complex system of horizontal and vertical passages inside the furnace must have a cross-section and length sufficient for natural draft. Turns of the chimney duct are made with a larger cross-section of 10–30%, due to the inhibition of the flow of hot air when obstacles arise.

- An incorrectly selected chimney cross-section and height can cause a burning smell in the house. The specificity of gas removal by natural draft will not allow removing a large amount of smoke through a hole of small diameter.

- The cross-sectional shape of the chimney also affects the quality of exhaust gas removal. In the corners of rectangular structures, vortices are formed, inhibiting the movement of hot air masses.

- The absence of metal liners inside the chimney slows down the movement of smoke inside the system due to surface unevenness.

- Inspection doors for cleaning furnace ducts may not close tightly. This impairs draft and allows combustion products to remain in the house.

- An error in the construction of the chimney will lead to poor smoke removal from the stove. The exhaust pipe located on the side surface of the roof must be higher than the ridge if the distance to it is less than 2 meters.

- The presence of several fireboxes in a furnace requires proper separation between them. Incorrect design of the partition will lead to poor traction.

- The collapse of a brick at a chimney bend is often the cause of poor exhaust gas removal.

- The connection of the stove ducts to the pipe should not be narrowed or made in a shape different from the chimney.Reducing the diameter of the connection will allow a large amount of soot to accumulate and impede the movement of hot air currents.

IMPORTANT! The furnace installation must be carried out by a qualified craftsman. A seam that bursts after drying or a cracked brick can cause poor smoke emission. It is very difficult to identify such a reason during operation!

The accumulation of soot in the internal cavity of the smoke exhaust channels of the furnace and chimney pipe is a common cause of deterioration in the draft of furnace equipment. What is being done to eliminate this deficiency? Use a brush with a weight and clean the vertical cavities of the chimney. To clean horizontal channels, special inspection doors are used and ash is removed through them.

The accumulation of soot in the internal cavity of the smoke exhaust channels of the furnace and chimney pipe is a common cause of deterioration in the draft of furnace equipment. What is being done to eliminate this deficiency? Use a brush with a weight and clean the vertical cavities of the chimney. To clean horizontal channels, special inspection doors are used and ash is removed through them.

ATTENTION! When constructing furnace equipment, masonry is carried out using clay mortar or mixtures specially designed for fireboxes. Using a conventional mortar based on sand and cement can cause cracks, and subsequently a decrease in efficiency and poor smoke removal.

Metal chimneys are cleaned using aspen logs. Given the complexity of ignition, the firebox is first heated using birch or oak, and then aspen is burned. The absence of resinous impurities during combustion, with a completely open ashpit, allows you to remove soot from the channels by burning out. This method requires compliance with safety measures due to the increased combustion temperature and the possible appearance of sparks in the chimney.

This type of cleaning is done using potato peels or rock salt sprinkled on burning coals. Substances that are released when these elements are burned make it possible to remove soot from hard-to-reach places in smoke exhaust ducts.The chemical industry produces special powders that, when burned, help clean the chimney.

IMPORTANT! Burning special mixtures for cleaning discharge channels and pipes allows you to remove a layer of soot up to 5 mm. With a larger amount of carbon deposits, the effect is achieved only by mechanical cleaning and ash removal using special devices.

External factors of poor traction

The appearance of a burning smell during operation of the stove indicates the occurrence of undesirable phenomena that impair the operation of the chimney. Such reasons may be the following factors:

- Improper organization of ventilation inside the room affects the draft: wide open windows located above the firebox level will disrupt the air flow inside the stove, especially when igniting in a cooled room, and completely closed windows and doors contribute to a lack of air inside the building, create a vacuum and periodically reverse cravings

- Strong gusty winds often cause disruption to the normal removal of smoke. To eliminate this phenomenon, special chimney caps are used that do not allow gusts of wind to disrupt the draft of the stove.

- Increased humidity, accompanied by precipitation and a decrease in atmospheric pressure, reduces the speed of movement of exhaust gases through the chimney channels, which leads to the appearance of an unpleasant odor in the house. To maintain normal draft, during precipitation, complex chimney channels are neglected: the ignition dampers are opened and the path of hot air flows inside the furnace equipment is shortened.

How to improve oven draft

To avoid the appearance of an unpleasant burning smell in the room, it is necessary to regularly clean the smoke exhaust channels and pipes. If the house is located in a windy place, a deflector is installed at the end of the pipe, which allows you to stabilize the draft, regardless of gusts of wind.

IMPORTANT! It is recommended to warm up the chimney before lighting the stove. To do this, they use paper, which is burned, the internal cavity is heated and the “air plug” is removed.

Insulating the chimney can significantly improve smoke removal. Such work is performed using special basalt wool, which is not affected by high temperatures.

REFERENCE! The vacuum of a cold chimney system pipe is 30% lower than that of a heated one.

If serious design flaws in the furnace are discovered that require constant improvement of smoke removal, a complex but effective method of forced removal of exhaust gases using a fan is used. Using this method will avoid the appearance of a burning smell, but will require power supply.

The quality of removal of combustion products from the furnace is determined by the correct design and regular maintenance of the chimney system. The construction of furnace equipment with good draft should only be carried out by experienced craftsmen. The frequency of maintenance depends on the operating mode of the furnace (at least once a year). Maintaining chimney ducts in good condition will ensure clean air inside a country house.