What mortar is needed for laying a stove?

In order to build a heating structure, you need to know what kind of mortar is needed for laying the stove. Indeed, a lot can depend on it: service life, quality of construction and much more. Therefore, it is so important to carefully select the composition, proportions and take into account some nuances. This will be discussed in this article; we will understand which solution is better.

The content of the article

Clay masonry mortar

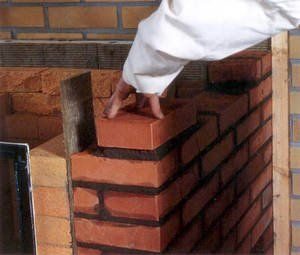

To ensure heat resistance and linear expansion, it is advisable to choose the right materials for construction.

IMPORTANT! It is worth remembering that the described mixture has not only the property of low bond strength, but also a decrease in the completeness of the layer. Therefore, there is a possibility of conversion from high to low thrust.

How to prepare clay

The preparation process is necessary so that the product acquires its characteristic properties. This is presented as a step-by-step algorithm:

Cleansing. The action occurs in a dry manner, that is, the substance is sifted through a sieve (the cells of which are less than 2 * 2.5 millimeters). This eliminates various impurities and contaminants. The only thing is that difficulties may arise due to the rapid clogging of particles. To do this, you can use liquid to moisten the soil.

Cleansing. The action occurs in a dry manner, that is, the substance is sifted through a sieve (the cells of which are less than 2 * 2.5 millimeters). This eliminates various impurities and contaminants. The only thing is that difficulties may arise due to the rapid clogging of particles. To do this, you can use liquid to moisten the soil.- Preparation. First you need to take a container.The substance is placed in it so that a layer with a thickness of approximately 150-120 mm is formed. Next, water is poured in. It should completely cover the surface with an elevation of 1 centimeter. Then the clay mass is also placed on top. Similar manipulations are performed until the capacity is completely filled. Then, after one day has passed, you need to move the resulting mixture. Next, add more liquid and let it brew for 24 hours. Readiness means that after this time you stir the product again.

Proportions of clay and sand

In aspect, there is a relationship between the ratio of the named substances and the fat content, which is inherent in the material. There are two varieties:

- Normal. To make it you will need 5 parts of clay.

REFERENCE! They should all be equal. Moreover, they have previously undergone a cleaning process. In each of them, except the first, sand is added in the following proportions: 1/10, 1/4, 3/4 and in the last one to one.

- Fat. Naturally, the proportionality in this situation will be different from the previous one. To begin with, 5 servings are also prepared and the first of them does not require any transformation. But with others it happens like this: 50% and 100% sand are poured into the second and third ones, respectively. As for the fourth and fifth, it's 1/1.5 and 1/2.

Ordinary clay solution

The factor influencing the composition of the substance is the intensity of heating. In different places of the structure it has different parameters. But in each case the layer should not exceed three to four mm. If it is denser, the strength of the structure becomes less. So there are two areas:

- Thermal storage. It is characterized by heating up to 600 degrees. The difference is the fact that this area does not interact with open fire.

- Fluff. The temperature indicator is lower - 400′ heat.

Fireclay clay mortar

The composition of the preparation includes substances such as fireclay soil and sand. The first of them makes up 30% of the entire part, the second - 70%. But it may be that the fat content is too high. It is then that you can change the proportions to 1:1. The described solution should be neglected when the fire chamber is being manufactured; moreover, it must be entirely constructed of fireclay.

Clay for stove masonry

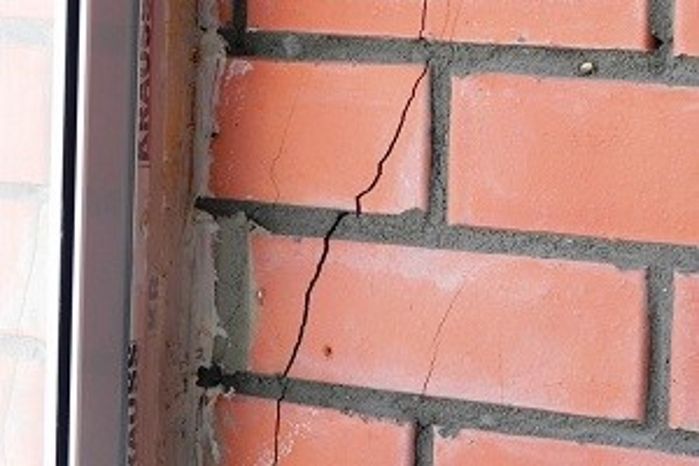

The substance differs from all others like it in that it is characterized by elasticity, strength, water resistance and ductility. It will be ideal if the clay is of medium fat content. Otherwise, for example, when it is greasy, it will cause damage when moisture evaporates from the surface. When thin - the absence of all characteristic and necessary qualities. To find a truly suitable product, you should search in the depths of the river banks, that is, where the layers have already been exposed.

How to choose clay for laying a stove

To choose the best option, it is advisable to carry out a preliminary check. There are several ways. These include:

Drying. Within three days, it should absorb the water that you previously added to the mixture. If it is not cracked, then the product is good.

Drying. Within three days, it should absorb the water that you previously added to the mixture. If it is not cracked, then the product is good.- With the help of a fun. When stirring, it may become sticky. This means high fat content.

- A ball formed from the mixture and liquid is placed between two planks. After which it is determined: many cracks - the substance is greasy.

- The same indicator can be checked due to the absence of rupture when bending a clay flagellum.