How to dilute clay to putty a stove

It would seem that with the arrival of gas in rural homes, stove heating is a thing of the past. But modern rich cottages are increasingly equipped not only with fireplaces, but also with entire stove complexes. It's stylish, environmentally friendly and fashionable. The crackling of wood and the play of flames give unprecedented comfort. Accordingly, the problems of maintaining the stove in working order returned.

It would seem that with the arrival of gas in rural homes, stove heating is a thing of the past. But modern rich cottages are increasingly equipped not only with fireplaces, but also with entire stove complexes. It's stylish, environmentally friendly and fashionable. The crackling of wood and the play of flames give unprecedented comfort. Accordingly, the problems of maintaining the stove in working order returned.

The content of the article

Causes of cracks in the stove

Stove masonry and the layer of plaster on the fireplace tend to crack over time. It is important to distinguish between minor cosmetic defects and real problems that require an immediate call to the stove technician.

- Hair-thin cracks appear on the seams of the stove during heating and disappear when it cools. Such defects are absolutely not dangerous and do not require intervention. If you really don’t like their appearance, just cover the walls with tiles and the problem will be eliminated.

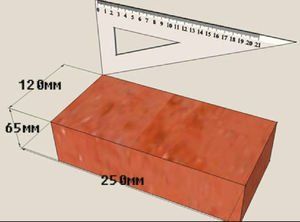

- Cracks of 1 millimeter or more that appear at the seams between the bricks and do not disappear when the stove cools down indicate an incorrectly selected masonry mortar. The different expansion coefficients of brick and clay cause warping and cracking.

- Large cracks and displacement of bricks are most often caused by overheating of the stove or improper air circulation system in the chimney and firebox. If the “overheating” of the stove is the fault of the owner of the house, then improper heat removal, when some areas become hot while others remain slightly warm, is the fault of the stove master.

- Closed, broken cracks that cross the walls horizontally or vertically at the seams are a sign that not everything is in order with the foundation. This problem can affect both new stoves and old ones that have stood for many years. There is no point in covering up these cracks; the stove needs to be urgently rebuilt before it completely collapses.

Next, we’ll figure out how to “treat” stove defects in cases where it is necessary.

How to dilute clay to putty a stove

Despite the sea of modern technologies for laying stoves, fireplaces, fireplace complexes and all kinds of heating and decorative innovations, stoves are still laid using clay mortar. They also use it to repair, plaster, and correct defects in masonry. Ready-made clay stove mixtures have appeared in building materials stores. Unfortunately, it is only suitable for working with fireclay bricks, where ordinary clay will not work. In other cases, to prepare a masonry or coating mixture, you will have to look for clay yourself.

How to make a clay mixture

It is necessary to distinguish between the process of plastering a stove for whitewashing and the process of sealing cracks in masonry joints. Accordingly, the solution will require different thicknesses and compositions. The ideal clay for coating and repair is the same clay from which bricks are made. Unfortunately, they stopped making bricks on their own long ago, preferring to buy them, and therefore it’s impossible to find a “deposit” for them.

It is necessary to distinguish between the process of plastering a stove for whitewashing and the process of sealing cracks in masonry joints. Accordingly, the solution will require different thicknesses and compositions. The ideal clay for coating and repair is the same clay from which bricks are made. Unfortunately, they stopped making bricks on their own long ago, preferring to buy them, and therefore it’s impossible to find a “deposit” for them.

You should choose low-fat red clay, and if necessary, additionally deplete it with sand. The mixture for sealing cracks in seams is prepared as follows:

- We take a clay-sand mixture and experimentally determine the required proportions of the components. To do this, prepare a plasticine-like solution and roll small balls from it (no more than 2 mm in diameter).

- We stretch our hand with the clay ball forward and drop it on the floor. If the ball does not crack or smear with a blot, then this is an ideal mixture for repairing stove seams.

- Add finely chopped straw for reinforcement and 1 kg of salt per bucket of the mixture. You can start working.

The solution for plastering the stove is prepared in a similar way, only its consistency is creamy.

How to coat a stove

When starting repairs, you should warm up the stove a little before work. The procedure for sealing cracks in the furnace is as follows:

- remove all the crumbling layer and all the lime whitewash (clay will not fall on it);

- spray or wet the repair areas with a brush so that the dry areas bond better with the repair solution and do not draw moisture from it;

- seal the seams tightly with a plasticine-like mixture, and plaster the surface with a liquid solution.

You can coat the oven by hand or use a spatula and trowel. After the solution has dried, additionally coat small cracks.

IMPORTANT! Do not heat the stove until the clay has completely dried and the damp areas have disappeared!

What other grouting products are there?

There are many different recipes for coating stoves and fireplaces, fireboxes and chimneys. None of them can be called the best; each is used in different conditions and to solve different problems:

- Tiled stoves are repaired with a mixture of alabaster and chalk, so the seams look neater.In addition, you can add different colors to such a solution, highlighting or hiding the joints between the tiles.

- Sauna stoves and stoves made of raw brick are repaired with clay mortar with the addition of horse manure. Underdigested blades of grass become excellent reinforcement for seams and cracks, and manure makes the plaster more durable and flexible at the same time.

- Mortars for masonry and plastering of stoves in which peat briquettes or coal are burned require putty with high heating resistance.

The following can be used as putty:

- Ready-made fireclay-clay mixture from a hardware store.

- A solution prepared from sulfur, lard and resin in a ratio of 100:2:2. Heat it to the state of syrup, then add fine glass in the form of a powder so that plasticine is obtained. This mixture is used to repair tiled stoves and is used to putty seams and cracks between tiles.

- A mixture of sifted clay and metal filings, potassium permanganate, salt, borax and water in a ratio of 2:2:1:0.5:0.5 and a dough-like consistency, ideal for repairing fireboxes and joints between hobs and doors with masonry. It does not crack from vibration and overheating.

- Fine wood ash in combination with clay, salt and water is also used to seal cracks at the joints of materials with different thermal conductivities.

- When repairing fireplace portals, fireplace areas and cladding, a mixture of gum and alabaster is used in a ratio of 1:4, diluted in liquid borax. After the solution dries, it is difficult to distinguish it from marble by color and hardness.

How to fire a stove correctly to avoid cracks

As mentioned above, one of the common causes of cracking of masonry is the so-called overheating.This happens when the oven is operated incorrectly, heats up too much or suddenly cools down. The most susceptible to this are stoves in country houses, where the owners come only occasionally in winter.

But you can also reheat the stove of a residential building, which operates throughout the winter. Smooth heating, ignition at full throttle and with the ash pan and damper open, as well as the use of the correct fuel, guarantees a long service life of the stove and no cracks.