How to make a melting furnace from an induction cooker

In everyday life, we use household appliances and sometimes don’t even think about the principles of their operation. With the development of technological progress, new developments and devices come into life. One of these is an induction cooker. The principle of its operation is based on the sequential transformation of energy from electrical to electromagnetic, and then to thermal energy. At the moment there are no options with high efficiency.

In everyday life, we use household appliances and sometimes don’t even think about the principles of their operation. With the development of technological progress, new developments and devices come into life. One of these is an induction cooker. The principle of its operation is based on the sequential transformation of energy from electrical to electromagnetic, and then to thermal energy. At the moment there are no options with high efficiency.

Induction cookers have a number of features.

- Fast heating with low power consumption.

- The food is obtained without smoke, bitter smell and harmful microelements.

- The stove only heats the food in the dish, so it is impossible to get burned on it.

An additional advantage of an induction cooker is the ability to use its qualities for other purposes, for example, to create a melting furnace.

The content of the article

Converting an induction cooker into a melting furnace

If you need a small smelter not for a large scale, but for your own needs with a maximum volume of 1 liter, you can make it from an induction-type tile.

Due to its advantages and ability to convert electromagnetic waves into heating energy, it is perfect for such purposes.

You will need to make some changes to the design, add a few parts, redo the body, and you will have what you need.

This DIY model will be very convenient to use and will save money.

Important! The process of creating a melting furnace will require knowledge and time, so carefully study all the theoretical fundamentals and read the instructions. If you doubt that you can complete everything, then it is better to entrust it to professionals.

What parts are needed for a homemade induction furnace?

Before you begin making a homemade melting furnace based on the operating principle of an induction cooker, you will need to collect the necessary elements. And if necessary, purchase missing parts.

To work you will need the following.

- Induction cooker.

- Copper tube with a diameter of 8 mm and a length of 3 m.

- Capacitor.

- Switch.

- Incandescent lamp for control.

- Crucible.

Advice. The quality and speed of melting will be largely determined by the power of the generator, lamps and the frequency at which the load is carried out.

How to make an induction melter from a stove

- It is necessary to twist an inductor from a copper pipe that goes from flat (at the bottom) to cylindrical (at the top). It turns out to be a kind of glass made of copper coils. Make it the size you need.

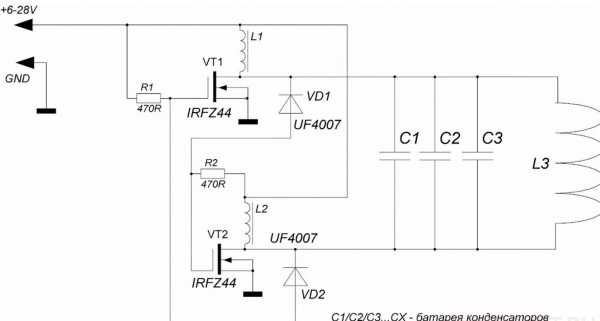

- Connect the entire structure according to the electrical diagram. Use a capacitor and a light bulb in parallel in a circuit.

- To get started, turn on the electric stove, place metal in the crucible located inside the inductor and press the switch of our product.

This device is the simplest and most convenient to use. It doesn't change the design of the tile itself, so anyone can do it.

Reference. The temperature is approximately 1000 °C, which is quite enough even to melt silver.

Useful tips for making a melting furnace from an induction cooker

To perform the work correctly and achieve the result you need, we will give you some useful tips. They will come in handy when making homemade equipment.

- If you need such a furnace to heat a room, use nichrome; graphite in a spiral is suitable for melting.

- The higher the frequency and power, the greater the efficiency. But the main thing here is not to overdo it.

- Use powerful light bulbs in the product, but no more than four in one design.

Of course, using such instructions it will not be possible to assemble a full-fledged furnace for melting metals. Such designs are simply not intended for such work, but you can get a device for light loads and small volume. This is quite enough for personal needs. If you need greater results and productivity, then you should definitely consider purchasing a quality smelter.