What is furnace lining

In construction, lining is a finishing used to protect any structures from various negative impacts. Moreover, the appearance of such a coating does not matter. When constructing a furnace, the lining is used to line the inside of the chamber. Its main task is to ensure protection of the walls and other elements of the firebox from possible damage during operation that may arise as a result of thermal, mechanical, and chemical effects. Thanks to the lining, the service life of the furnace increases.

In construction, lining is a finishing used to protect any structures from various negative impacts. Moreover, the appearance of such a coating does not matter. When constructing a furnace, the lining is used to line the inside of the chamber. Its main task is to ensure protection of the walls and other elements of the firebox from possible damage during operation that may arise as a result of thermal, mechanical, and chemical effects. Thanks to the lining, the service life of the furnace increases.

The content of the article

What is furnace lining and in what cases is it used?

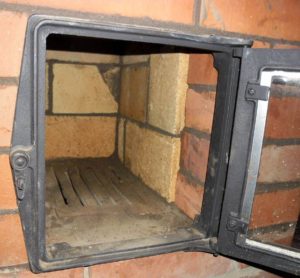

One of the main factors in the construction of brick stoves is the proper design of the firebox, because this element of this heating structure is most exposed to high temperatures. Brick, which is used during the laying of the stove, under the influence of fire, can burn and become deformed due to lack of moisture. To avoid this and extend the service life of heating structures, as well as ensure the safety of people when operating the furnace, the brick must be protected from fire. This is what the lining is designed for.

One of the main factors in the construction of brick stoves is the proper design of the firebox, because this element of this heating structure is most exposed to high temperatures. Brick, which is used during the laying of the stove, under the influence of fire, can burn and become deformed due to lack of moisture. To avoid this and extend the service life of heating structures, as well as ensure the safety of people when operating the furnace, the brick must be protected from fire. This is what the lining is designed for.

REFERENCE! It should be noted that the surface of the walls of the chamber of a metal stove and solid fuel boilers also requires protection.This is necessary to ensure that metal and steel panels do not burn out during operation. For this reason, many manufacturers equip the furnaces of steel devices with kaolin and fireclay panels.

Most furnace owners think about lining. During its construction, it is important to correctly calculate the thickness of the material, otherwise the walls of the stove will not be able to warm up well. Heat can only penetrate into the chimney, but not into the room. The efficiency of the furnace may decrease noticeably, which can lead to increased fuel costs, because it will be required in much larger quantities to heat the thick walls of the chamber.

Methods for carrying out lining

Lining is carried out in different ways. The appropriate method is selected depending on the material from which the stove is built. Methods for constructing protection:

- lining the inside of the stove with ready-made fireclay bricks that can withstand any temperature - this method is popular due to the fact that the material, with excellent protective qualities, is also very cheap;

- installation of heat-reflecting screens - effective for metal stoves used in baths;

- the use of hewn stone from natural rocks - sandstone or quartz;

- the use of rolled materials or plates - basalt fiber, cardboard or kaolin paper, vermiculite boards;

- coating the walls with special solutions or substances - fireclay or mullite mixtures, sold in stores.

IMPORTANT! The advantage of using mortar for lining is that it can be used to create an absolutely monolithic surface, which will become an ideal fence that protects the brick from fire.The disadvantage of such a lining is that it will require repairs faster than masonry made of stone or fireclay bricks.

Using fireproof adhesive for lining

To bond various materials used to construct the internal, protective surface of the firebox, it is better to use fire-resistant, high-temperature glue. It will flawlessly fasten refractory bricks or slabs made of basalt fibers. The glue is sold in special containers, after opening which the mass is thoroughly mixed. Before applying glue to the surface, it should be moistened. The thickness of the coating is 3 mm; if, apart from the lining glue, nothing else will be used, then you need to apply several layers of it, with an interval of 15 minutes. The protective layer dries in about a day.

It is better to entrust lining work to professionals. High-quality implementation of this task will allow you not to think about stove repair for a long time.