How to thread an overlocker

A sewing machine can be threaded in many ways, none of which will cause defects in the form of gaps when stitching the material, or the unexpected appearance of overcast stitches. In this regard, the overlocker is a more capricious device. If the thread is not attached to at least one of several loopers, this is fraught with the appearance of gaps or overcast stitches in the seam line. Therefore, the process of thread direction in an overlocker should be taken very seriously.

A sewing machine can be threaded in many ways, none of which will cause defects in the form of gaps when stitching the material, or the unexpected appearance of overcast stitches. In this regard, the overlocker is a more capricious device. If the thread is not attached to at least one of several loopers, this is fraught with the appearance of gaps or overcast stitches in the seam line. Therefore, the process of thread direction in an overlocker should be taken very seriously.

The content of the article

General refueling scheme

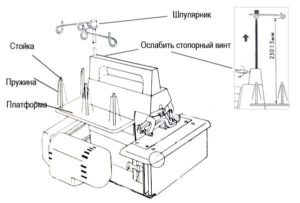

To correctly thread the overlocker, you must perform certain steps in the correct sequence:

- place a spool of thread on the holder;

- Thread one end of the thread through all the holes intended for it. To ensure that the stitches come out smooth and beautiful, the spool holder rod is directed directly in the direction of the thread movement;

- It is important to correctly thread the thread through all tension devices: one of them pulls the thread to the side, the other tightens it. Therefore, the sequence of thread direction must be observed. In modern overlockers, these devices have been combined into one, which performs both actions;

- insert the thread into the looper so that it moves perpendicular to the movement of the material while sewing;

- When the thread can be pulled out from under the foot pressing it, it means that the threading has come to an end.

Important! It is advisable to check whether the thread is correctly fixed in the overlocker. To do this, you need to practice on unnecessary material. If the thread breaks while sewing or makes a strange loop, it means that it was threaded incorrectly somewhere.

Refilling a Chinese three-thread overlocker

The most famous representatives are class 51 overlocker, as well as the companies Typical and fn2 7d. He earned his popularity thanks to such facts as:

- Possibility of use not only in professional workshops, but also at home;

- Unlike its counterparts, which can only handle delicate fabrics, it can also work on thick, hard or rough fabrics.

If you learn how to thread it, then in subsequent work you can fix the threads on any model of this type of device, since the sequence remains the same:

- Insert the thread into all the holes located on the body of the device, which are intended for their direction.

- Including the thread must be in the tension device.

- Then it is taken down, threaded through the eye of the needle and out through the foot.

- Practice on a test piece of fabric.

The tension device is usually located in the right looper. This should be taken into account when refueling. If the thread needs to be fixed inside all overlock fastenings, then multi-colored types can be used. This trick will help you correctly figure out which thread needs to be released at the moment and which one needs to be pulled up.

Reference! The left looper is much more difficult to access than the right looper. Therefore, experienced seamstresses use tweezers when threading.And if you fail to get one end of the thread into the hole, it is advisable to remove the plate from the needle and try again.

Threading a four-thread overlocker

The process of fixing a thread in a 3-thread machine is practically no different from the same sequence of actions on a 4-thread machine. There are just a couple of differences:

- The left needle thread tensioner has a thread with a left needle, and the right one has a thread with a right needle.

- On the right side, the first looper thread tension device belongs to the first looper on the left side, and the first looper thread tension device on the left side corresponds to the first looper on the right side.

But there are other ways to thread a four-thread overlocker. As a rule, the manufacturer indicates them on the equipment case.

Attention! There are models of four-thread overlockers equipped with the F.A. system. S.T., which helps thread the thread into the looper located below. It also makes threading through the upper loopers easier.

Refilling scheme for overlocker class 51

Any instruction for threading a Chinese overlocker is based on a certain sequence of actions:

- You need to start fixing the thread from the looper located on the left side. The thread is inserted into the hole in the protective right cover, through a device that guides it, and then through the hole in the left cover.

- Then the thread is passed through all the holes located in the thread tension device. It is passed around it, then threaded into the channel, which directs the thread to the looper itself.

- Next, the pulley is turned clockwise until the looper, which is on the right, is at the top above the throat plate.

- Then, keeping to the back direction, the thread is passed around the lever where the right looper is located and hooked to the hook.

- Then the pulley is rotated again so that the left looper is at the bottom. Next, the thread is passed through the hole located in the looper and the pulley continues to turn until the right looper is again above the needle plate to lift the left looper up. When it takes the upper position, the thread is fixed under the shoulder blade. If a mistake is made somewhere at this stage, it will tear during operation.

- Now you can work on the right looper. The thread is passed through a hole in the plate of the needle thread tension device. Then it is directed through the hole in the knife plate located on top, which in turn is an element of the looper thread tension device on the right side.

- The pulley is tightened until the right looper reaches the top position. The thread is inserted into its hole under the hook, which gives impetus to the final direction of the thread.

- At the final stage, the needle thread is passed through the tension device, then through the hole in the plate, going around the regulator rod.

- The thread is fixed under the hook, then threaded through the eye of the needle.

There are many videos that clearly show how to thread an overlocker.

What tools are needed to thread and adjust the overlocker?

Such moments can be determined during the work process. As a rule, the necessary additional tools depend on which particular part of the overlocker needs to be adjusted at the moment:

- Adjustment of threads. To do this, you need to have four reels of different colors. If the equipment is three-strand, then there are three coils.

- Checking the quality of stitches.In this case, you will need a piece of fabric from any material on which you can test how an overlock sews and then throw it away without regret.

- Thread the thread into the left looper hole. Due to its location, it is not as easy to get to as some people think. Regular eyebrow tweezers will greatly facilitate this process.

- The overlock needle is bent or broken. In the same category of problems is missing stitches in the seam line. A common mistake made by beginners who either installed it incorrectly or pulled the material too hard with their hands. Therefore, it is always advisable to have spare needles on hand.

- Overheating of the overlocking equipment or its failure. The reason is the lack or lack of lubrication. At a minimum, it should be used once every 6 months. A syringe that can be filled with oil is suitable for this. It will perfectly reach and lubricate all hard-to-reach areas.

- Overlock knives do not work. A common mistake made by new owners of an overlock machine is that they start cutting and processing all possible materials that they have access to at the moment. This is a wrong judgment. The original purpose of overlock knives is to process protruding threads and trim the edges of very delicate and bulk materials. Therefore, for a novice user of such a machine, it is better to always have a spare set of knives on hand.

You need to thread the overlocker correctly, as this can extend the life of the device and prevent various types of breakdowns.