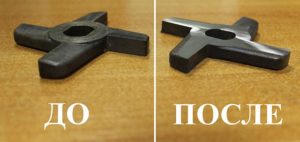

How to sharpen a meat grinder knife

The modern kitchen is equipped with a large number of household appliances and auxiliary items. This includes a meat grinder - an indispensable assistant when grinding raw meat.

The modern kitchen is equipped with a large number of household appliances and auxiliary items. This includes a meat grinder - an indispensable assistant when grinding raw meat.

Due to frequent use, the knife, the main element for grinding the product, begins to lose its cutting properties.

A few simple ways will help you avoid this and extend its service life. We'll tell you how to sharpen the knives of the device yourself.

The content of the article

The need for sharpening

A mechanical meat grinder, despite the wide selection of modern, improved household appliances, still remains the most relevant device for processing raw meat into minced meat. It greatly facilitates the housewife’s chores in the kitchen and is a faithful assistant.

The meat grinder consists of several components that complement each other's work. The most significant is the knife, which bears the bulk of the load. It finely chops the incoming pieces of meat, facilitating its passage to the grate, which helps obtain finished minced meat.

When to sharpen

Over time, the knife begins to lose its functions as a cutter.

This can happen for two reasons.

- Metal tends to oxidize.This leads to the formation of a rusty coating on the surface of the knife and makes it difficult to operate.

- Tendons and small bones settle on the chisels of the knife. To grind them, the cutting element uses more force, which leads to a decrease in sharpness.

If the functionality decreases, the meat begins to wrap around the screw and knife. Therefore, if stable operation decreases, it is necessary to immediately begin sharpening its components.

Sharpening methods

Many consumers are mistaken in the belief that knives need urgent replacement after they fail. This method will negatively affect financial costs. After all, frequent use of a meat grinder will lead to constant purchases of its components.

A dull knife can be “reanimated” using several suitable methods:

- grinder;

- grindstone;

- sandpaper.

15–30 minutes of free time and the proper use of the right materials will help restore the functionality of the knife in the meat grinder.

Reference. These options can be used to sharpen knives of both manual and electric meat grinders.

How to sharpen knives yourself

Preparatory process

Before you start sharpening, it is recommended to prepare the materials for work. For example, tools can be lubricated with sunflower oil. This will avoid chipping and damage during the sharpening process. Waiting time - 5 minutes. After this, you can proceed to direct sharpening of the cutting units.

Important! Experts recommend sharpening the grill along with the knife. Because with prolonged use, rust deposits, chips and damage appear on it.

Let's look at each method in more detail.

Using a sharpening machine

The method of sharpening cutting objects using a sharpening machine is the most popular. It stands out among others for its speed and efficiency with minimal time investment.

The sharpening machine is equipped with a special disk with an abrasive structure. Before carrying out repair procedures, the surface of the disc must be treated with a special abrasive paste and wait for it to dry completely. The surface of the disk acquires a rough structure.

After all the required preparatory processes have been completed, you can begin the process of sharpening the cutting elements. The processing of a knife takes place in several stages.

- First of all, each of the four blades of the knife is processed. To do this, you need to press them evenly against the rotating disk. An important aspect is maintaining a tilt angle of 80 degrees. This necessity is a big disadvantage for users who have not previously used a sharpening machine on the farm.

- Let's move on to the second stage. During the processing of the blades, small burrs appear. They negatively affect the operation of the knife, so they must be eliminated. To do this, the surface of the material being processed is carefully pressed against a rotating disk, observing the frequency and force of pressure.

After carrying out the necessary manipulations, the knife can again be used in a manual or electric meat grinder to grind meat into minced meat.

Use of whetstone

Processing with a whetstone has deservedly enjoyed great success. It is characterized by fast and effective results.

If you don’t have a sharpening stone in your pantry at home, you can purchase one from a specialty store.

The processing process itself has some peculiarities.If you correctly follow all the necessary rules, work to restore the functionality of the knife will be quite easy and will not take much time.

- It is recommended to sharpen cutting parts under running cold water. The ideal option would be a sink. Water is used for a lubricating effect and cooling of metal products during operation.

- For reliable fixation, you can place a piece of dense material under the stone. The fabric will fix the position of the working tool and prevent it from sliding on the surface of the sink.

- The knife itself is placed on a stone, leaning the blade against it. Don't forget about the presence of water.

- Maintaining light and even pressure, the knife blade must be moved clockwise until completely cleaned. A shiny surface indicates a successful job.

- After finishing sharpening, it is recommended to rinse the tool and check the fit of the cutter to the grid. To do this, both components are added together. The absence of gaps indicates successful completion of the work.

The tools are ready to use.

Working with sandpaper

Every man has an emery cloth in his toolbox. It is used in many areas. Sandpaper is also suitable for sharpening sharp objects.

Advice. For processing knives, experts recommend using a fine-grained sheet. Paper with a large web can cause additional damage during repairs.

- For the repair procedure to proceed successfully, the sanding cloth must be placed on a hard, flat surface. The most suitable option for this would be a desk or kitchen table.

- Corners can be secured with heavy objects. This will help fix the working material.

- Before starting work, it is advisable to lubricate the knives with sunflower oil. Oil acts as a lubricant and is used for improved gliding.

- You can start sharpening 5–10 minutes after it has dried.

- Before starting work, additional processing with a fine file may be required. It is necessary to remove chips, scratches and other damage.

- To achieve the goal, you need to move the knife across the paper in different directions until a uniform shine is obtained.

- It is recommended to perform movements over the entire surface of the paper. The appearance of shine is the first sign of a successfully completed job.

- After finishing, the cutter must be washed to remove any resulting contaminants and checked.

- The knife and the grill are connected to each other. The absence of gaps and gaps guarantees the correct result.

Now the meat grinder components are ready for use.

Proper sharpening: useful tips

Before actually carrying out work processes, it is recommended that you familiarize yourself with several rules and tips. They will help you approach the matter competently and sharpen the components of the meat grinder yourself without putting in extra effort.

- The first thing to note is the importance of the grid. Components such as the knife and the grid are directly dependent on each other and complement the work of each. Therefore, when processing the cutter, the grate also needs to be cleaned and sharpened. The methods are the same. The only exception: when sharpening on a sharpening machine, you should immediately proceed to the second point.

- You should not start working on a sharpening machine without special skills. This may cause injury. Lack of practice will also lead to breakdown of the meat grinder components.

- A whetstone is a fairly expensive piece of equipment, so it is advisable to purchase it if you use it regularly. If this is not possible, but you want to sharpen your knives in exactly this way, it is better to turn to a specialized service from professionals.

- The presence of a lubricant is mandatory. It softens the progress of work, improves the removal of rusty deposits and helps protect the external structure of the tools from additional damage. These include abrasive paste, water and vegetable oil.

- At the end of the sharpening process, special attention should be paid to the absence of gaps and gaps between the knife and the grid. For the meat grinder to work properly, these components must be close to each other. If even small gaps appear, it is recommended to continue the process of cleaning and sharpening the cutting components.

Conclusion

The meat grinder has deservedly received a high position among kitchen utensils. It greatly facilitates the process of preparing dishes; it is impossible to imagine a modern kitchen without its presence.

Parts of a meat grinder, like any equipment, begin to fail over time. Under the influence of negative factors, cutting elements lose their positive qualities.

The occurrence of malfunctions of the knife and grate leads to disruption of the overall operation. To avoid this, it is necessary to sharpen products in a timely manner, following a few simple rules.

Such actions will help solve the problem and extend the life of a mechanical or electric meat grinder.

it was possible to explain everything in a nutshell - a flat surface, sandpaper and move it here and there... a lot of words about rust - where does it come from??? There is oxidation, it’s pointless to argue with that. everything in the world oxidizes)) and rust is sometimes even beneficial, an example is a file. thank you for reading to the end))

High-quality sharpening is possible only on a surface grinding machine. The rest is from the evil one.

Thank you very much for your very reasonable and thorough recommendations!

Sandpaper should never be used. This method will ruin the cross. The best way is to grind the knives on a grinding machine; more precisely, there is only one method, this is manual finishing.

Sir, you are an amateur in this matter.

The one who wrote about methods for sharpening meat grinder knives is ABSOLUTELY not

knows how to do this. He would also advise sharpening the scissors after cutting

sandpaper. Where were you taught this “art”? Do you even have

idea about metalworking? Your knowledge is at the vocational school level, but

Fortunately, they don’t teach such idiocy there. Read the "Handbook"

sharpener" to understand what can be sharpened with sandpaper. If

I want to learn how to sharpen cutting tools, write to me for soap. I will explain everything to you correctly. And no discs or grinding

powders And don't fool people's heads. Everything is much simpler.

So you brainiacs painted on km of tape, who knows how to sharpen it and make it confusing

The article, like many others like it, contains false information.You can resort to sharpening the knife if all the causes of poor grinding have been eliminated. The main reason for the poor performance of meat grinders is the gap between the knife and the meat exit mesh, which allows meat fibers and veins to be wound around the knife, because the knife can only cut if it touches the steel mesh tightly. You will not need any sharpening of the knife if the knife will slide tightly on the steel grate. In such a tight combination, when working, the knife has the property of self-sharpening, and all these tales that meat grinder knives need to be sharpened are from specialists who do not know the principle of operation of a meat grinder knife. Remember, if in your meat grinder there is never a gap between the knife and the steel mesh for minced meat or other substance to come out, then you will never need to sharpen the knife if it is made of high-quality steel.

...should not be done in the absence of special skills...