Microwave spot welding

A welding machine is useful to every craftsman. It is used to work with many products. To purchase it, you do not have to go to a specialized store. You can make a resistance welding machine yourself from an old microwave oven, using the necessary knowledge and a little imagination.

The content of the article

Definition

The spot welding machine stands out among others for its functionality with little time consumption. It is used to connect two metal parts. At the moment of heating with the help of electricity, adhesion of the surfaces is formed. This guarantees the strength of the connection. The device itself reaches small sizes and is controlled manually.

Consumables

A microwave oven is a useful kitchen appliance. In the modern world it is present in almost every home. Special specialists have found use for it not only in the culinary field.

From the components of the furnace, you can assemble a large number of useful devices, including a spot welding machine.

For production you will need:

- microwave transformer;

- tape winding;

- electrodes;

- wires for the bundle;

- control parts (lever and switch).

After preparing the consumables, you can begin the installation and assembly process.

Stages of work

The workflow takes a minimum amount of time and knowledge.Following the established instructions and observing safety precautions, anyone can assemble a welding machine from an old microwave oven.

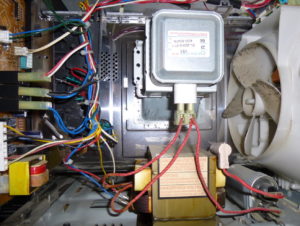

The first step is to remove the transformer. The rear housing must be removed with care. The transformer should be removed carefully, without using heavy or sharp objects in the process. The use of additional materials will cause serious damage. Such actions will provoke the causes of its malfunction.

For the manufacture of a spot welding machine, it is recommended to use transformers from more powerful models of microwave ovens. They have improved functionality and will be more reliable during operation.

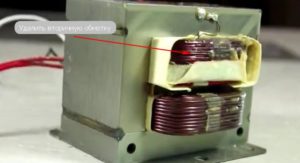

After removal, one of its windings is removed - the secondary one. When carrying out dismantling work, you can use auxiliary tools to make the work easier (the main thing is accuracy). If restrictive shunts are detected, their removal is also recommended. The primary winding is left due to the use of denser wire and fewer turns.

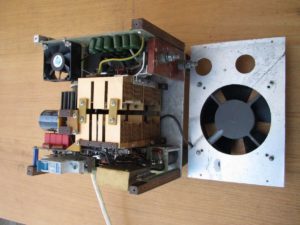

After removal, a new coil is attached. To do this, it is better to use a wire with a diameter of at least 1 cm. After such an upgrade, the transformer is again ready for use. It will serve as the basis of the welding machine.

The next step is to attach the electrodes. When selecting, experts recommend paying close attention to the correspondence of the diameter of the electrode to the diameter of the connecting wires. Small copper rods are perfect for this.

It is recommended to use electrodes of a minimum length. This will ensure consistently high power of the device. For large component diameters, special tips can be used.

For installation, the tip and electrode are connected using bolts or nuts. It is better to use copper as a connecting material. Among others, they stand out for their minimal electrical resistance. This will ensure that there is no loss of power.

Attaching the controls will not take much time. These include the lever and switch.

The lever controls the power flow between the part being repaired and the electrodes. The base of the lever is attached to the primary winding circuit, to the movable electrode. Connection to the secondary winding is not recommended. This will cause significant power outages or cause a short circuit.

The length of the lever is selected depending on personal preferences and convenience required during the work process.

The switch supplies electricity from the base to the welding electrodes. It is also connected to the primary winding.

It is recommended to place the switch directly above the lever. This will provide additional convenience when working with the welding machine.

Exploitation

A spot welding machine made from microwave oven components is not only easy to assemble. The main advantage is the favorable pricing policy: the costs of the components are minimal. In most cases, they are absent altogether, since all the necessary components are already available in your personal toolbox. A finished device on a store window does not always attract the attention of buyers due to its rather high price. Self-assembly of a spot welding machine from a microwave is a profitable solution.

It is advisable that the device be equipped with a fan. If this is not possible, it must be turned off periodically during use to cool the parts.

Conclusion

The spot cooking apparatus is used for a wide range of services. You can assemble the device yourself from parts of an old or faulty microwave oven, saving a significant amount of money. Having a personal welding machine will also save personal time, because there will be no need to contact specialized centers. With proper workflow and compliance with operating rules, the device will serve its manufacturer for a long time.

A wire with a diameter of 1 cm, which the author of the article recommends, has a cross-section of 0.9 square meters. cm or 90 sq. mm. Author, how are you going to bend it? The number of turns is at the discretion of the reader. Create, invent, try! If I could give the article a “-1”, I would.