How to sharpen a hand saw

Often people carrying out repairs are faced with a situation where a tool that has served faithfully begins to fail. In such situations it becomes quite offensive. Because you don’t always have the strength to do repairs, but you want to do them without any problems. This article will tell you how to sharpen a handsaw.

Often people carrying out repairs are faced with a situation where a tool that has served faithfully begins to fail. In such situations it becomes quite offensive. Because you don’t always have the strength to do repairs, but you want to do them without any problems. This article will tell you how to sharpen a handsaw.

The content of the article

Basic rules for sharpening a hand saw

In order to carry out correct and correct sharpening, you need to get the hang of this tricky business. You should have an excellent eye, not be distracted while working, and hold your tools confidently. While working, you need to build on these rules:

- Securely fix the saw blade. It is best to secure it in a strong vice. We pass wooden planks between the canvas so as not to crush the instrument.

- Use only proven products. A file will work great, followed by a needle file or a file with a fine notch. Any file will do, ideally a recently purchased one. If this is not available, it is better to rub the old one with a steel brush and charcoal.

- You need to be extremely careful when sharpening. The file will ideally pass through the metal and capture the top layer of the blade. If one tool overheats or becomes clogged, it should be replaced with another.

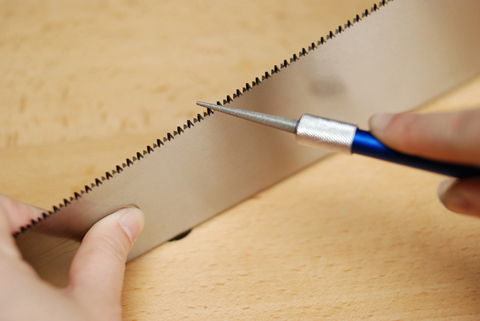

- When sharpening, follow the rules for holding materials.The handle should be clasped with the right hand, and the end should be clamped with the left. The pressure on the hacksaw should be as even and smooth as possible. It is necessary to make movements only in one direction.

- You should grind off as even an amount of metal as possible from the material. If done incorrectly, the blade can become even more dull and clogged. It is better to immediately decide on a certain number of movements and pressure force so that the sharpening is uniform.

Reference! Burrs that appear during sharpening are removed using a file with a velvet side.

How to sharpen it yourself: step by step

To ensure that everything goes at the highest level, we carry out the procedure of separating the teeth. This is done to ensure that the saw moves freely on the wooden material without constant jamming. With the routing, along with an increase in the width of the cut, a large amount of chips will come out, which will not get stuck in the material.

- The wiring should be done one by one, gradually changing the differences between the links. The difference should not exceed more than one millimeter.

- After this work, you can proceed directly to sharpening the material.

crosscut saw

To sharpen a cross-section hacksaw, you should choose a triangular file that is suitable for the hardness of the material. The angle should not exceed or be less than 60 degrees.

Initially, you should start along the left edges of the odd teeth. After this, we go along the right edges of the odd ones. Thus, we sharpen the edges of the sharp end. Next, you should do the same procedure with the remaining teeth.

Rip saw

For longitudinal tools, a coarsely cut needle file or a diamond-shaped file is used. Triangular tools are not suitable for this type of work.

The material is installed vertically.During operation, you should press the tool to the metal at an angle of 90 degrees, picking up the sharpening material from the back and front sides. This improves the quality of the distant row of teeth. After this, the canvas is turned over and the work is repeated.

Mixed cutting saw

To restore the quality of work, use files with a medium notch or diamond-shaped files with a fine abrasive. When working, use a gap angle of 90 and 75 degrees, respectively.

If you don’t have any skills, then it’s better to turn to specialists so as not to damage the instrument.