How to instantly sharpen drill bits yourself

Drills can be very different, however, most often craftsmen give preference to those that can help in working with even the most durable materials. Anyone can understand that they need sharpening. To do this, just start the work process.

The content of the article

How to understand that a drill needs sharpening

If the drill has become too dull, then this will be evident at least from the result: it will not be possible to make a hole. Despite the fact that all modern drills are made from special grades of steel and are also subjected to a procedure such as hardening, over time they still become dull.

If the drill has become too dull, then this will be evident at least from the result: it will not be possible to make a hole. Despite the fact that all modern drills are made from special grades of steel and are also subjected to a procedure such as hardening, over time they still become dull.

IMPORTANT! A responsible master always pays attention to the condition of the tool even before he starts work. If it seems too dull, then this is not a reason to throw it away, because everyone can restore its functionality with their own hands. You need to use a simple sharpening machine, which is also called an electric sander. This device will allow you to correct the situation and solve all problems as quickly as possible.

You also need to take into account that sharpening can have different sizes and depends both on the technical characteristics of the product (diameter) and on the characteristics of its use.For example, some options are needed for working with soft metals, while others are needed for working with hard metals. It is quite natural that they can differ greatly from each other, which also needs to be taken into account before you start sharpening.

To summarize, we can say that even someone who does not have much experience can understand the need for sharpening. This is a feasible task even for those who are picking up a drill for the first time. You just need to carefully observe the process. If it goes very tightly, then most likely the problem lies in insufficient sharpening.

Typically, the need to sharpen a drill arises after prolonged work with particularly hard and durable materials.

Set drill sharpening parameters

In order to quickly restore the geometric parameters of the product, you need to act slowly and carefully, otherwise it will break.

In order to quickly restore the geometric parameters of the product, you need to act slowly and carefully, otherwise it will break.

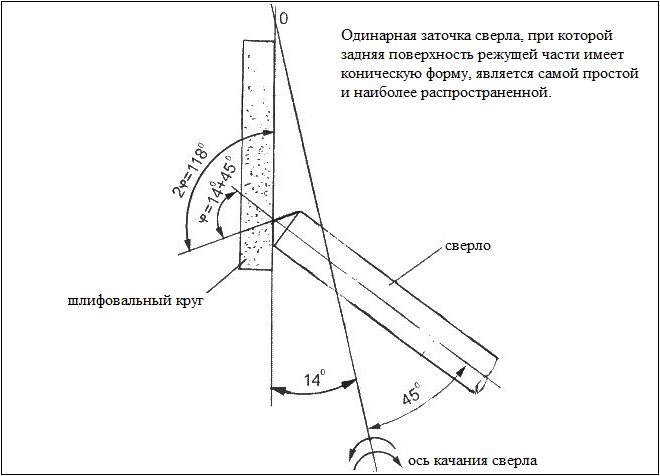

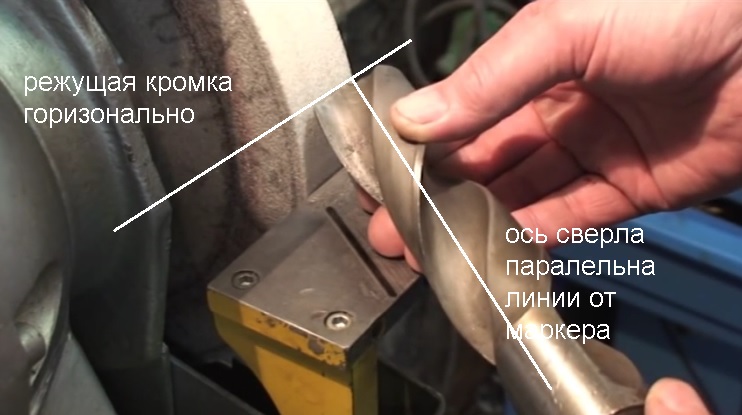

During sharpening, the edge should be parallel to the working surface of the sharpener axis. Otherwise, you will not be able to achieve success. Every master should know about this. When sharpening, you need to act gradually. If you rush, you can easily break the product or render it inoperable, even on a new and expensive machine. This is possible even if we are talking about an experienced master.

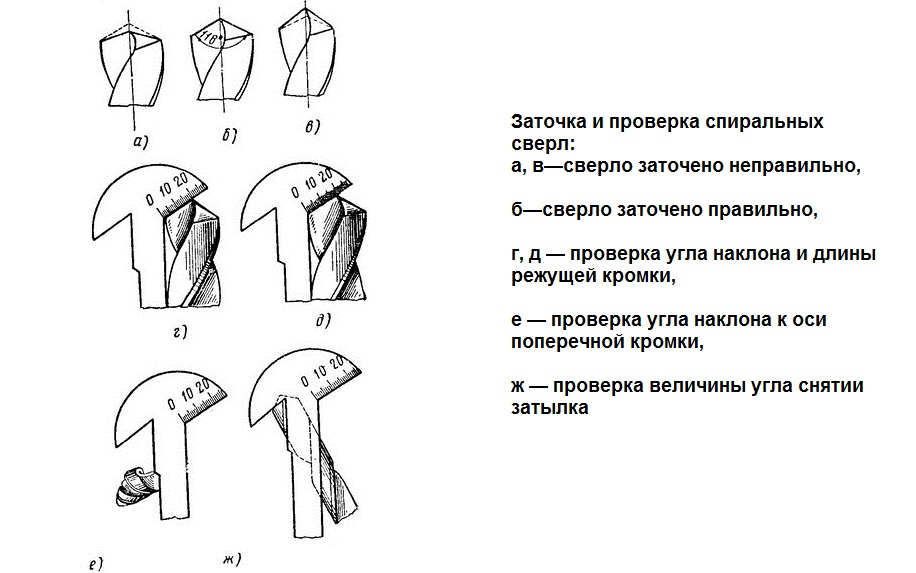

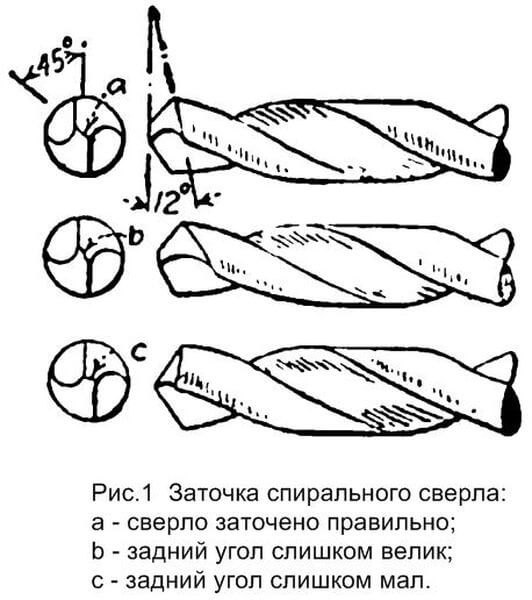

The most important parameters that need to be taken into account during sharpening are the total length of the cutting edges, as well as the angle of the tool. If you ignore these parameters, then the most serious problems may arise.

What you need to sharpen a drill at home

You need to purchase an emery machine, as well as a grinding wheel. This will be quite enough.If you buy additional tools, the process will become even simpler, however, some tools are too expensive, so it is important to determine in advance the acceptable cost of each individual tool. Otherwise, the cost of home sharpening will be too high and it will be more profitable to turn to professionals who have extensive experience.

You need to purchase an emery machine, as well as a grinding wheel. This will be quite enough.If you buy additional tools, the process will become even simpler, however, some tools are too expensive, so it is important to determine in advance the acceptable cost of each individual tool. Otherwise, the cost of home sharpening will be too high and it will be more profitable to turn to professionals who have extensive experience.

It is almost impossible to quickly process metal without tools, which is why it is so important to acquire all the equipment on time. With their help, you can significantly speed up the procedure and achieve excellent results in an extremely short period of time. This is especially important if you urgently need to make a hole in a hard surface.

IMPORTANT INFORMATION! All drills that are used for working with metal have to be sharpened quite often. Options used for wood processing can boast a much longer “lifespan.” The thing is that wood is a relatively soft material that does not require too expensive drills. It can be handled even by those who do not have much experience. With metal, everything is completely different, which is why it is so important to know in advance what exactly you need to sharpen the drill for. Some craftsmen use blunt products when drilling a metal surface. They end up spending a lot of time on just one small hole, which is why it's important to prepare in advance.

How to sharpen a concrete drill yourself

Many people are very afraid of the sharpening process. They think it's too difficult. Indeed, self-sharpening is associated with a number of difficulties, so it often becomes impossible for an inexperienced craftsman.Most often the problem affects people whose eyesight is too poor.

Many people are very afraid of the sharpening process. They think it's too difficult. Indeed, self-sharpening is associated with a number of difficulties, so it often becomes impossible for an inexperienced craftsman.Most often the problem affects people whose eyesight is too poor.

In this case, it is best to purchase a machine for home sharpening. You can find relatively inexpensive machines made in China. You just need to follow the instructions that come with the machine. You can also sharpen a drill using a regular grinder, but this method is only suitable for experienced craftsmen who are well versed in repairs and know exactly what needs to be done.

Do-it-yourself metal drill sharpening

Sharpening a metal product is a particularly complex process. If the drill is dull, then further work makes no sense. It will lose its surface sharpness too quickly. Only after you have managed to find a high-quality tool can you start sharpening.

Sharpening a metal product is a particularly complex process. If the drill is dull, then further work makes no sense. It will lose its surface sharpness too quickly. Only after you have managed to find a high-quality tool can you start sharpening.

To do this, you need to find a special machine and make sure that the angles at which the drill is located in relation to the plane of the material are correct. You can find out the correct angles from the instructions for the machine. If such instructions are not at hand, then you will have to study the Internet and try to find instructions that will indicate all the useful information.

When choosing a machine, it is recommended to consider a number of factors. It is best to read reviews on specialized resources and study customer reviews. Then no problems will definitely arise.

Sharpening a tipped pobedite drill

Every modern tipped drill, despite its strength, will sooner or later become dull. In order to restore the previous efficiency, you will have to use a diamond wheel. Before you start the sharpening process, you need to make sure that the total height of the part (cutting) is at least 1 cm. All work must be done at the lowest speed.This is necessary so as not to accidentally break the tool.

Every modern tipped drill, despite its strength, will sooner or later become dull. In order to restore the previous efficiency, you will have to use a diamond wheel. Before you start the sharpening process, you need to make sure that the total height of the part (cutting) is at least 1 cm. All work must be done at the lowest speed.This is necessary so as not to accidentally break the tool.

Another tip: you need to grind the working surface of the drill before soldering. It is recommended to grind even the front surface. This is especially important if the plate has worn down almost to the drill. The front surface must be processed in such a way that the level of soldering thickness becomes much smaller.

Despite numerous difficulties, it is impossible to do without sharpening. A drill that is too dull will not allow you to perform simple work with concrete or metal, which is especially important during repair or construction work. Sharpening for the first time can be challenging, but over time the process will seem fairly simple. You need to be careful and not make too sudden movements. Then the instrument will not break and will serve its owner for another year.

Useful tips from professionals

- A drill is a technically complex tool that requires the sharpest possible drill bits. Otherwise, it will be impossible to make at least one hole in metal, concrete or wood. It is recommended to use special drill attachments that will facilitate this process and allow you to maintain the sharpness of the drill for a very long time.

- It is recommended to carry out the sharpening process as often as possible. Then you can get rid of unnecessary problems associated with lack of time, because many people find out that the drill is dull right before starting work.

- The type of metal that needs to be drilled affects the sharpening angle. If you forget about this, you will have to do all the work again, since the drill will very quickly become unusable.

- Proper storage will increase its service life. You need to use stands and pencil cases.

You need to write books. What machine? Who has it? At best, a “sharpener” or grinder. And for the inexperienced, one condition: after sharpening, grind off the heel, and you will be happy. Yes, the drill will be more delicate, more fragile and the cutting edge will break faster. But drill it!!!

There is a channel on YouTube. Victor Leontyev. drill sharpening he has a lot of useful videos on locksmithing

By the way, the photo in the article seems to be from his channel. probably article correspondence video

The author does not attach importance to processing the jumper and sharpening the ribbon. does not consider double sharpening of the head.

This author has no concept of cutting theory at all...

But I didn’t have enough specifics! The main information is that drills need to be sharpened. And if you don’t sharpen it, it’s impossible to work. Therefore it is necessary to sharpen. And - for a specific task. Sharpen. Drill.

Actually, the title says how to sharpen it instantly, but the author is talking all sorts of crap from books that everyone has read more than once. In short, the article is about nothing

I thought I was the only one with this opinion.

Firstly, the author has no idea about the technology of cold metal cutting. For different materials and different grades of steel used drills, and not only: cutters, cutters, taps, dies, reamers.The more competent the selection of drill steel used for the material being processed, the longer the drill will serve. Secondly, the author missed the most important point - cutting speed. Each material has its own cutting speed. Without understanding this, any processing tool can be ruined very quickly. And thirdly, it is a lubricant, which also plays an important role in the processing of materials. The lubricant can be simply water, oil, kerosene, as well as the simplest emulsion. And one last thing. A good mechanic or turner will sharpen a drill without any angle gauges, because each material has its own sharpening angle.

Advice to the author. Before writing such articles, simply study the materiel!

The best video tutorials on sharpening twist drills, hammer drills, types of sharpening, all on Viktor Leontiev’s YouTube channel. I advise you to look!

The best video tutorial on sharpening drills and other cutting tools is to do it yourself and learn from your own mistakes. Personally, I was taught this way.

instantly sharpen drill bits yourself, my friend, you are a storyteller. But if you can do it with your teeth. Before writing, sharpen the drill instantly, and then tell us how to do it INSTANTLY.

The theory is dry, my friend... Emulsion, water... lard, this is the best lubricant. If you have ever stood behind a machine, then refrain from such moralizing!

From the world according to the author's thoughts - jeans. Nothing practical. The general theory is “nothing.”

Practice is much easier and more difficult.

What kind of smart guy is this guy who wrote this article? In children They know in the garden that if a drill doesn’t drill, it means it’s dull.Damn, I read all of this and was offended. An upstart and a very stupid upstart at that. Who wrote this?)))))))))

No instructions will help, all you need is experience. The most important thing is that the heel is lower than the cutting part and the cutting parts are symmetrical. and you have to choose the angle depending on what you are drilling. I remember when I was a student, the foreman gave me a bunch of broken drills and a couple of sharp ones and sent me to sandpaper to train. That’s how I learned it over time; I haven’t sharpened it for about thirty years. But even now, give me a drill and I’ll sharpen it the first time, remember those little hands!

The photo is a clear example of how you can be left without fingers that are located between the drill being sharpened and the stop pad.

so many dozens of “stupid” people came up with the “Theory of cutting materials”... and then one damn genius declares that this is not simple, but VERY simple - sharpening drills... if you sharpen drills like the author advises, then we will soon not then we will develop further, but we will return to stone axes...there a hole (not a hole) can be made with his (the author’s) drills...and I have only one question for the author - what is “WIN”?

Probably, in the opinion of the author, this is the one who said “I will conquer all drills.”

I'll win on the blue circle. Or rather, I sharpened it before. Now a hammer drill. Several years ago I called a “handyman” to install a new lock on a steel door. His drills did not “take” the steel of my door. I offered him mine. Things went like clockwork. "Maestro" asked - whose production? I don't know. I sharpen it myself. He asked to be imprisoned. Sharpened a full box in 19 minutes. Including burnt ones. Although everyone knows that burnt ones are thrown away.

Well done! I had a similar story many years ago with a lock on the stairwell. The new neighbor decided to install a new lock on the metal door. I was returning home, and he was just working magic on the castle. I asked him if he needed help. He told me that he could handle it himself. However, half an hour later he called and said that his drill was dull and couldn’t drill anything. Then I took this drill, sharpened it and drilled all the necessary holes at low speeds. He was very surprised that the drill worked better at low speeds than at high speeds, that it was useless. You probably came across the same “specialist” in locks.

It is useful for the author to sharpen at least one drill according to his “instructions”

When I worked at a factory, I sharpened thousands of drills, but if I had started with such “instructions,” I would not have sharpened a single one!

Well, how to sharpen a drill instantly?...

“During sharpening, the edge should be parallel to the working surface of the sharpener axis.”

I finally guessed about the “edge”: this is the cutting surface of the drill. But I can’t understand what “the working surface of the sharpening axis” is. Apparently there is not enough higher education...

To teach something to others, you first need to learn how to correctly express your thoughts yourself.

That was a long time ago. Around '69. Served urgently. There was a woman at the headquarters, a safety engineer. Before demobilization, everyone took chords. So we encountered it. She began to teach us how to hammer nails. Everything is according to the instructions, according to the book. And we just asked to demonstrate it with our own hands. She didn't come to us anymore. Author, turn to any guy in the garage, he will teach you this, you won’t read it in any book.The reason he is a man is because his hands grow properly!

(What is needed to sharpen a drill at home? You need to purchase an emery machine, as well as a sharpening wheel. This will be quite enough) or into hardware for 100 rubles maximum, by the way, I learned to sharpen it myself when I had to drill a lot at work, but there was an emery machine, as well as grinding wheel

From this article I understood one thing: it is necessary to sharpen the drills, otherwise it is impossible to work.

Andrey, only the machine is called a grinding wheel, an emery wheel

I also sharpened it on a grinder on a grinder, but what about wood drills, round ones (who knows what they are for, I know)

How to sharpen a drill at home? Yeah! Everyone has a sharpening machine in their apartment to sharpen a drill! Not everyone can sharpen yet! Simply fucked up. Just so they would read the article? For show, so to speak.

Grinding machines, abrasive wheels, and sandpaper is paper!!! For different types of wood and different types of metal, drills with different sharpening angles and drilling speeds are used!!! In Soviet schools they taught this in labor lessons!!!

He writes that if something is not clear, look for information on the internet. Also, to find out the sharpening angles of the drill, he suggests buying a special machine so that you can read about these angles in the instructions for the machine.

And by the way, my drill is not for a drill, but for a drilling machine, please give me other instructions.

How to quickly sharpen a drill? You need to act SLOWLY! But how to sharpen quickly?

Experience is required however!

Well, well, good on paper, but in reality, wow