How to choose filters for a water well

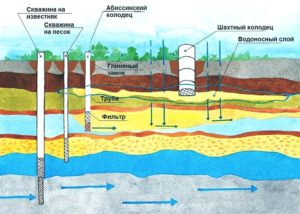

Filters for water purification are used not only in autonomous water supply systems. The quality of water supplied through central water supply networks is increasingly causing complaints from consumers. Impurities, organic compounds, chemical elements negatively affect health. But if, when using a centralized water supply, the consumer can carry out cleaning only at the final stage, then when using autonomous systems (wells, boreholes), cleaning can be carried out comprehensively.

Filters for water purification are used not only in autonomous water supply systems. The quality of water supplied through central water supply networks is increasingly causing complaints from consumers. Impurities, organic compounds, chemical elements negatively affect health. But if, when using a centralized water supply, the consumer can carry out cleaning only at the final stage, then when using autonomous systems (wells, boreholes), cleaning can be carried out comprehensively.

When drilling and constructing a well, specialists are required to offer the best design option for the filters that need to be installed. But in practice, the main indicator on which they rely is the absence of visually observable impurities. It also happens that the choice of the required design is shifted to the owner of the well. Therefore, it is necessary to have at least a general idea of what type of filter will be optimal in a particular situation.

The content of the article

Types of filters

All used filters can be divided into two groups.

Coarse filters

Perforated, slotted, mesh mostly used for pre-filtration (purification) of water coming from the aquifer.

Installed directly into the well to prevent impurities from entering the water intake system (pipes, pumping equipment).

Fine filters

These filters must be used to remove water-soluble chemical compounds (hydrogen sulfide, chlorine, iron, manganese salts, lime), which negatively affect the taste of water and can negatively affect health.

Important! Any well must be equipped with an additional natural filter made from natural materials of various fractions (sand, gravel, crushed stone).

This material is poured after the casing string is lowered into the well. It is located between the well wall and the outer surface of the casing pipes.

Filter selection

When deciding how to choose a specific design of water treatment systems, you should focus on certain nuances.

Influence of locality of residence choice

To select pre-filters, the main indicators that you should pay attention to are the hydrogeological characteristics of the rocks at the location of the well.

The choice is made depending on the fractional composition of the rocks entering the well along with water.

For more refined purification, it will be necessary to obtain an expert opinion on the chemical composition of the water.

Important! The sample is taken after pumping the well in a volume of not 10 m³.

The chemical composition of water is influenced by several factors.

These include:

- characteristics of the constituent rocks;

- the presence of objects near the well that can influence the chemical composition of soils (industrial enterprises, landfills).

Filter Height Determination

A water filter installed directly into a well can be a separate element installed at the bottom of the pipes. It can also be done on the pipe itself. In both cases, it is necessary to calculate the height of the filter element structure.

Reference. The height of the filter element is usually taken from the calculation of the expected daily debit and the thickness of the aquifer. It is determined during the drilling process.

The structure should always be located between the base of the aquifer and the water level (in the lower third).

Review of filters produced by different companies

It is worth considering filters from manufacturing companies, domestic or foreign, based on several parameters. These include the cost of the product, the complexity of installation and maintenance, the availability of components and warranty periods.

"AQUAPHOR"

AQUAFOR products are available in various designs.

Storage containers (jugs, dispensers) are equipped with replaceable cartridges. The devices are convenient and mobile, but do not provide high throughput.

Flow-type designs are capable of ensuring an uninterrupted cleaning process from the smallest impurities through the use of replaceable cartridges. They are also able to get rid of most harmful chemical elements.

"FIBOS"

Flow-type water purification systems "FIBOS" ("PREMIUM", "MINI", "FIBOS1") are characterized by high performance. Manufactured using modern high-tech materials for use as cleaning elements (fiberglass coated wire).

They are completely autonomous, equipped with automatic flushing drives, and do not require cartridge replacement for a long time (up to 10 years).

"ZEPTER"

produces exclusively high-tech equipment. The offered models are flow-through multi-stage filtration systems with an automated (electronic) system for setting up control of water supply and purification.

produces exclusively high-tech equipment. The offered models are flow-through multi-stage filtration systems with an automated (electronic) system for setting up control of water supply and purification.

Distinctive features are complete safety during operation (protection against leaks, indication of the need to replace the filter element).