What is catalytic oven cleaning?

Catalytic oven cleaning is the reaction of the breakdown of fats, soot and other substances into simple organic compounds, water, carbon, etc. To do this, special plates are installed on the walls of the oven and enamel is applied. It consists of:

- Oxidative chemical catalysts;

- An absorbent consisting of nanoparticles;

- Substrates (porous and non-porous).

The content of the article

Impact principle

The work of this method lies in the breakdown of various compounds that accumulate on the walls during the cooking process, which are subsequently removed by a sorbent from nanoparticles.

The work of this method lies in the breakdown of various compounds that accumulate on the walls during the cooking process, which are subsequently removed by a sorbent from nanoparticles.

The purification process is carried out directly during cooking at an average temperature of 200 degrees (more effective cleaning and breakdown of fats and soot occurs at a higher temperature). Chemical compounds are absolutely harmless to the human body and will not affect the final result of cooking in any way.

To activate the process, you only need to turn on the oven. Regardless of the set mode, chemical reactions take effect.

Process Features

The main advantage and feature of this process is, as mentioned earlier, the automatic activation of cleansing substances during the cooking process.

The second advantage is that you can choose where to apply the fat-absorbing compounds.It is recommended to apply it to all oven walls and oven fan blades. It is highly not recommended to install enamel plates on the bottom of the oven; they will wear out after just a few cooking cycles. During the baking process, sugar and milk components often leak and settle, which the coating does not tolerate. Plates should not be installed on the inside of the door, otherwise it will interfere with monitoring the cooking process.

The second advantage is that you can choose where to apply the fat-absorbing compounds.It is recommended to apply it to all oven walls and oven fan blades. It is highly not recommended to install enamel plates on the bottom of the oven; they will wear out after just a few cooking cycles. During the baking process, sugar and milk components often leak and settle, which the coating does not tolerate. Plates should not be installed on the inside of the door, otherwise it will interfere with monitoring the cooking process.

IMPORTANT! If unwanted substances get on the plates, you need to carefully remove them using a mild detergent and a soft cloth.

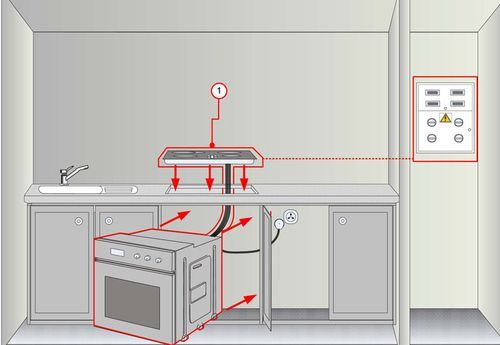

The catalytic cleaning method is suitable for both gas types of ovens and electric ovens. Regardless of the model and design, the connections act the same.

Pros and cons of the procedure

Among the advantages can be noted:

- Automation of the process by applying a substance to the walls and fan blades, as well as maintaining the desired temperature;

- Cost-effective, because cleansing is done during the cooking process and without unnecessary effort;

- Use in absolutely any types and models of ovens at different cooking temperatures;

- The minimum threshold for the start of the process of decomposition of fats and soot starts at 150 degrees, while with other methods this threshold is much higher;

- The composition is the same for all manufacturers of the substance. The difference can only be in the time of action;

- Relatively cheap substance.

Of the minuses it is worth noting:

Of the minuses it is worth noting:

- There are many types of cleaning ovens in the world, and this method is the least effective (manual washing of the chamber is not taken into account);

- Like many other products, it does not completely eliminate the problems of cleaning the oven.Over time, the grease-absorbing coating has to be changed, first washing the entire chamber;

- Sheets, grates, grills and other tools will need to be washed by hand;

- The bottom of the oven and the door from the inside will have to be washed by hand, because... special material is not installed there;

- If sticky, sweet, fermented milk products and substances get on the plates, cleansing will not work;

- This method is most beneficial for frequent cooking in the oven. If you use the oven only a couple of times a month, this cleaning option will not pay for itself;

- Clean the enamel coating only with soft cloths. When using rough and rough material, cracks may form and the plates will lose their effectiveness;

- The cost and quality of the installed enamel plates directly depends on the type of oven. What is suitable for an electric oven may not be suitable for a gas oven and vice versa;

- The validity period of special plates is approximately 5 years. After the expiration date, they need to be replaced to make cleaning more effective.

To summarize, it can be noted that this method is attractive because of its low cost and availability. Compared to other methods, catalytic purification does not require large amounts of electricity. Also, by using this type of cleaning, you can save a lot of time that would have been spent on washing the oven manually.

To summarize, it can be noted that this method is attractive because of its low cost and availability. Compared to other methods, catalytic purification does not require large amounts of electricity. Also, by using this type of cleaning, you can save a lot of time that would have been spent on washing the oven manually.

Today, almost all modern furnaces have built-in protection against the deposition of organic compounds and soot in the furnace, and the catalytic cleaning method is one of the most economical. No matter how attractive this automatic cleaning option may be, you need to take into account the costs of the grease-absorbing coating, which needs to be changed periodically.