DIY distiller

The variety of physical and chemical processes of converting liquids from one state to another allows the resulting products to be used both in everyday life and in industry. Distillation is one of the methods that alchemists have used since ancient times to change the properties of various consistencies.

The variety of physical and chemical processes of converting liquids from one state to another allows the resulting products to be used both in everyday life and in industry. Distillation is one of the methods that alchemists have used since ancient times to change the properties of various consistencies.

The content of the article

Why do you need a distiller?

The scope of use of devices for changing the properties of a liquid is very wide. They are used for the following purposes:

- purification of ethyl alcohol from impurities;

- creating perfumes using the method of isolating aromatic substances and essential oils;

- separation of petroleum products into different types of fuel and resins;

- purification of medical products;

- production of purified distilled water, which is widely used in the automotive and industrial sectors.

Depending on the tasks assigned, distillers have different sizes and the specifics of the physical and chemical process of distilling liquid from one state to another.

Design and principle of operation of the device

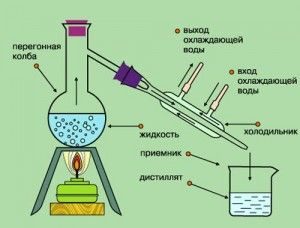

How a distiller works is known to every person who has had to deal with moonshine. An apparatus for distillation and purification of water works as follows:

- a large container with the original consistency is heated to boiling temperature and the heating is slowed down to maintain the evaporation process;

- droplets of steam accumulating in the upper part of the container are sent to a cooler (sometimes called an evaporator), which changes the properties and cleanses the liquid of unnecessary impurities;

- After conversion and purification, the resulting product is sent to a collection container.

The description is simple, but the distillation process is actually complex. The method of collecting steam in the upper part of the container can be performed with additional cooling of the upper cavity or using a funnel. And the cooler is made in the form of a separate vessel or spiral located in a container with a forced decrease in temperature, the value of which affects the quality of liquid purification. The material and diameter of the tubes, the number of turns of the spiral and the direction of vapor movement in the distillation system have a great influence on the quality of the purified water.

IMPORTANT! For proper operation of the equipment, the resulting steam must move through the pipelines and the evaporator from top to bottom!

The dimensions of household distillers capable of producing small amounts of purified water allow the equipment to be installed on the stove and kitchen table. The dimensions of industrial units depend on the volume of distillation and can occupy separate rooms or workshops.

REFERENCE! Purification using condensation of steam into liquid allows you to obtain products free of harmful impurities! Treatment of some specific diseases requires periodic consumption of distilled water!

If you frequently consume distilled products for technical or medical purposes, you sometimes have to deal with the low degree of purification of the purchased liquid. In order for the used water to meet the desired requirements, it is best to prepare it yourself, or rather, using a hand-made distiller.

What is needed to make a distiller with your own hands?

Before making the unit, you need to prepare two containers: one for boiling, the second for collecting purified water. The first one must be hermetically sealed; for this you can use an old kettle or pressure cooker. The second container is less demanding in terms of design features.

Before making the unit, you need to prepare two containers: one for boiling, the second for collecting purified water. The first one must be hermetically sealed; for this you can use an old kettle or pressure cooker. The second container is less demanding in terms of design features.

To make an evaporator and connect the vessels, you will need a metal tube, preferably made of brass, due to the flexibility of which a spiral is made. To make airtight connections between the container and the tube, you will need a plumbing tool, a soldering iron, clamps or wire. In addition, you will need a device for making a spiral, a coolant container and a hose of the appropriate diameter to connect all structural elements.

ATTENTION! Do not use old rusty pots or tubes to assemble the distiller! The selected material must be of good quality and not subject to corrosion or high temperature!

Before assembly, it is advisable to make a sketch reflecting the arrangement of components and connections of all elements of the assembled structure. The presence of such a drawing will help to assemble the unit.

The manufacturing process of the device

When assembling a distiller, several stages of work must be completed.

- A hole is made in the lid of the boiling container, which is equipped with a sealed flange pipe or a small piece of tube is soldered for subsequent connection to the steam removal hose.

- Check the closing plane of the lid for leaks.If this is not available, a rubber seal is made that can withstand boiling temperatures.

- After this, staples are made that will allow you to fix the lid in the closed position. If such fasteners are not available, use a heavy object to prevent the lid from bouncing and steam leaking during boiling.

- To make a spiral, use a cylindrical template in the form of a plastic pipe or other object. The diameter of the device is selected such that after twisting, the spiral fits into a pre-prepared cooling container.

- A hose is used to connect the boiling tank, the evaporator and the receiving tank. All hose connections are clamped with clamps or wire.

The distiller is ready for use. Pour water into the main container and cooler. All elements are placed one by one from top to bottom and water purification begins. Independent operation of such a unit will allow you to obtain the desired quality of liquid purification.

ATTENTION! Before purifying tap water, it must be left for at least eight hours! Neglecting this recommendation leads to a decrease in the degree of purification!

The manufactured distiller will purify water at home. If it is necessary to obtain essential oils, the manufacture of a more complex design is required.