Distiller - what is it?

Humanity has been drinking alcoholic beverages for a long time. To make alcohol-containing drinks, people created primitive devices. Over time, the devices were improved and supplemented.

How was alcohol created? We will consider the answer to this question in more detail in our article.

The content of the article

What is a distiller

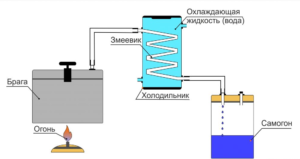

Many people wonder: what is a distiller? Let's try to figure this out. The main method for producing alcohol is the distillation process; a device that operates on its basis is called a distiller (moonshine still). The formation of alcohol in an alcohol distiller occurs through the processes of evaporation of the liquid part of the mash, followed by the collection of condensed vapor into a container. This action is called distillation.

If you use a distiller based on pure tap water, then as a result we will get crystal clear distilled water, purified from foreign impurities, salts and bacteria.

Types of devices

The quality of the alcohol produced largely depends on the types of devices and their constituent elements. Here are a few proven types of devices:

Alambik is a copper distiller, the most primitive of devices. The apparatus consists of a cube, a helmet, a coil, a static refrigerator, and a container for the final product.A direct-flow distiller gives us the opportunity to distill at home. The only drawback is that the productivity is low; fusel oils may end up in the drink. The distillate cannot be run again.

Alambik is a copper distiller, the most primitive of devices. The apparatus consists of a cube, a helmet, a coil, a static refrigerator, and a container for the final product.A direct-flow distiller gives us the opportunity to distill at home. The only drawback is that the productivity is low; fusel oils may end up in the drink. The distillate cannot be run again.- A distiller made of copper or stainless steel has a more advanced design. The design includes a cube, a steam chamber, a lid, a thermometer, a valve, a water cooling system with a pipe, a coil, and a fitting for inlet/outlet of liquid. There is a control valve on the steam pipe. There are models with separate glass parts - a diopter, a refrigerator. It has great performance and can also be used at home. The liquid is re-run to thoroughly clean fusel oils from alcohol.

IMPORTANT! An alcohol distiller with a drawer can be equipped with a rectification column.

- The most advanced is the third type of alcohol distiller equipped with a rectification column. It is equipped with a firebox, containers for water/mash/moonshine, a steam pipe, a pipeline for alcohol evaporation, a thermometer, a steamer, a jar, a pipeline to the filter, filters with copper plates, a coil, a cooling system, and a hydrometer. The design produces a 100% pure product. The only drawback is the high cost and bulkiness.

All presented types of distillers are designed to produce pure moonshine. You can independently control the distillation process, as a result of which you receive a high-quality product at an affordable cost.

Which one should you choose? For the production of grain, grape moonshine, whiskey or cognac, the first type is suitable - alambrik.The fragrant traditional moonshine will be produced by the second distiller, with a strengthening column. If you produce both in large volumes, you should choose a third apparatus with a distillation column. You can easily make high-quality moonshine or liqueur using it.

Main purpose

The internal structure of moonshine distillers is typical; four important components interact in them - a distillation cube, a coil, a cooler, and containers. In the distillation cube, the processes of separating alcohol from water occur. It is usually made from copper. The cooler is a water jacket that wraps around a coil; through cooling, the vapors in it are cooled. The coil is made of copper or stainless steel; the materials have good thermal conductivity. Accordingly, condensed steam is formed at the outlet and flows into the container.

Additional devices:

- A steam boiler is a container into which steam enters, then it cools, dividing into elements. In it, phlegm (liquid smelling like fusel) is partially separated. Alcohol-containing light vapors move further along the cooler coil. The distiller may have two steam chambers; aromatic herbs, zest, and spices are added to one of them to give a pleasant smell to the final product.

REFERENCE. The steamer is made of stainless steel. It looks like a flask with built-in fittings for inlet/outlet of steam.

- The reinforcing column (tsarga) is a long tube (40 cm) installed vertically to the distillation cube. Produces purified moonshine with a strength of 80–85%.

- The distillation column is a kind of multilayer filter (45 cm).At its levels, nozzles of different fillings are used (stainless steel or copper shavings, springs, crushed pieces of wire). Produces alcohol with a strength of up to 96 degrees.

Principle of operation

The most primitive moonshine still works according to the following technology: evaporate - cool - condense - collect.

Let's take a closer look at the internal interactions of the elements. When the original mash is heated, the liquid part (water + alcohol + impurities) evaporates. The steam is then further purified in a steam steamer before condensation. After which, the vapors entering the coil are cooled and condensation forms. Next, the resulting moonshine flows into a collection container. If after the first distillation the liquid flows into the container is cloudy, it means that the condensate contains a certain amount of impurities. Then a repeated cycle of fractional distillation is recommended.

IMPORTANT! Before the secondary distillation, the distillate is diluted with water to approximately 20–25 degrees of strength.

After completing the procedure, homemade moonshine is ready for use!