Replacing the valve on a gas cylinder yourself: how to unscrew it

The valve on the cylinder has 3 fittings that provide fuel supply and shut-off. If there is a smell of gas, as well as obvious external defects, the mechanism must be changed. Step-by-step instructions on how to unscrew the valve on a gas cylinder and how to select a new part can be found in the presented material.

The content of the article

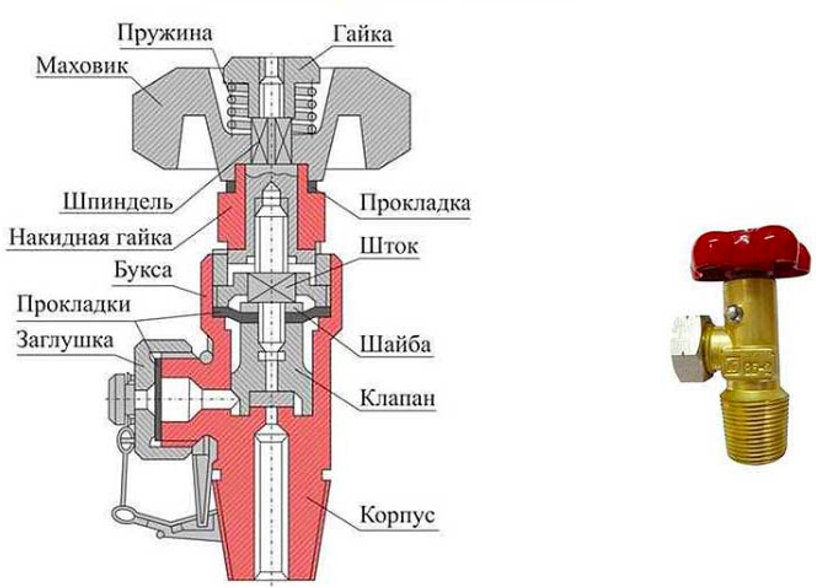

Design and types of valves

Replacing the valve on a gas cylinder is a necessary operation that must be performed periodically if the equipment wears out. To carry out work safely, it is first recommended to understand the structure of the mechanism, its types and markings.

The valve is located directly under the cylinder cap. It is manually screwed onto the thread, which is located on the neck. In this case, the valve itself is a tee with 3 outlets in the form of fittings:

- the top one has a flywheel that opens and closes the valve;

- the side one is needed for gas supply;

- the lower one is mounted directly on the cylinder.

When learning how to unscrew the tap on a gas cylinder, it is also recommended to familiarize yourself with the types of valves. The classification is related to what gas mixture is pumped into the cylinder - in accordance with this, the device is marked with its own marking:

- WB (with numbers 1, 2 or designation 2m) - these are standard elements that are placed on a cylinder with propane, butane or a mixture of them. Such elements are made from an alloy of brass, less often - steel.Therefore, it is not difficult to understand how to unscrew the tap from a red gas cylinder.

- Oxygen (indicated by KV or VK without numbers) - they are placed on containers with oxygen, the color is blue. Although the same valves can be installed on propane-butane tanks. They are also made of brass.

- Acetylene (designated VBA, also without numbers). They are mounted on white cylinders. Made from steel, they are not used in everyday life.

In what cases is replacement necessary?

Replacing the valve on a gas cylinder is necessary if at least one of the following symptoms is present:

- there is a noticeable crack on the body;

- there are traces of rust;

- dents and other defects;

- there is a smell of gas (in this case, it is necessary to check the tightness of the system and the hose as a whole - perhaps the reason is not related to the tap).

The valve on the gas cylinder is replaced independently or with the help of specialists. Moreover, it is done even without the manifestation of the described signs, for example, due to the expiration of a period of 5 years. This is the maximum period after which it is necessary to carry out a technical examination of the cylinder. If there are obvious defects, it is carried out earlier, after which permission is issued for further use or rejected.

Work order

The method for changing a valve on a gas method is quite simple, but requires the use of great effort, because the valve is screwed very deeply into the neck. Therefore, it is better to work together, and if this is not possible, it is necessary to ensure complete fixation of the cylinder. It can be welded to cast iron or steel structures. Another option is to temporarily weld a lever and use it to hold the container (again, with an assistant).

The instructions on how to unscrew the valve from a gas cylinder are as follows:

- Turn off the tank and open the tap.

- Take a gas key and place it on the neck.

- They begin to forcefully unscrew the valve.

- If you cannot budge it, the joint should be heated well.

- To change the valve on a gas cylinder, they begin to unscrew it with gentle and not very strong movements. If you work jerkily, there is a risk of breaking the thread. For the same reason, it is unacceptable to use a hammer or other heavy objects by hitting the gas key with them.

- Now it’s clear how to unscrew the valve from a gas cylinder. Over time it will give in and come off the thread easily. Next, you need to clean the container from condensation by draining it into a bucket.

- Then the surfaces are cleaned of contaminants, including grease.

- They install a new faucet, first applying sealing tape to the fitting so that the joint is airtight.

- In a similar way (but in the opposite direction) twist it until it stops.

How to check for leaks

Repairing a gas cylinder valve is simple, but it requires care, and most importantly, ensuring the tightness of the system to prevent gas leakage. It’s also quite easy to verify this:

- Prepare a concentrated soap solution in warm water.

- Apply it to the junction of the cylinder and the tap.

- Take a compressor and pump air inside at a constant pressure of 2 bar (2 atmospheres).

- Watch carefully to see if foam forms. If it is not there, the instructions on how to replace the valve on a gas cylinder have been followed correctly, and there is no need to worry about a leak.

- If bubbles form, you need to tighten the tap again and then repeat the test.

The procedure should be performed several times, first removing the soap solution and wiping the container with a rag, and then applying a new portion.If you correctly understand how to remove the valve from a gas cylinder, it is enough to perform 2-3 checks.

Thus, it is quite possible to repair the valve yourself, since it does not require special skills or equipment. But if you don’t understand how to change the gas tap, or you can’t ensure a tight seal, you need to turn to professionals.