Types of polyethylene pipes: what they are, what they look like, advantages, photos

PE pipe is a product made of polyethylene that has been processed under conditions of high pressure and hot temperatures. Such pipes are completely resistant to corrosion, so they greatly outperform their metal counterparts. However, they can withstand temperatures only up to 80-90 degrees, so they are limited in use. The main characteristics, pros and cons of such products are described below.

The content of the article

Characteristics and scope of application of polyethylene pipes

As the name suggests, all types of polyethylene pipes are made from the organic polymer of the same name. During the production process, the material is melted and softened, and plasticizers are introduced to improve elasticity. The result is a fairly dense raw material, which is molded into pipes of different diameters and lengths.

The PE pipe, the photo of which is shown below, has the following technical characteristics:

- diameter (outer) from 16 to 63 mm;

- wall thickness from 2 to 6 mm;

- minimum operating temperature 0°C;

- maximum operating temperature +90°C;

- maximum pressure 16 bar;

- the inner surface is smooth.

Due to the described technical characteristics, polyethylene pipes are used in different systems:

- cold water supply;

- sewerage;

- hot water supply;

- gas supply (subject to low pressure);

- watering plants (at the dacha, on farms);

- water heated floor;

- drainage systems;

- storm drains.

Sometimes polyethylene pipes, as in the photo, are used in heating systems. But this is only permissible in apartments and private houses, where the temperature of the riser and radiators usually does not exceed 80-85 degrees. As for the main line coming from the boiler room, it is always made of classic metal pipes, since at the outlet of the boiler the water warms up to 110-130 degrees.

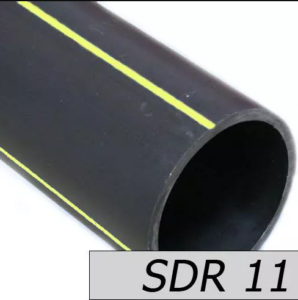

We can say that polyethylene pipes are products made from an organic polymer that is resistant to corrosion and moderately high temperatures. Sometimes they are designated with additional markings, so questions arise, for example, what is this – an SDR HDPE pipe? This is the name for products with a standard dimensional coefficient, which is defined as the ratio of the outer diameter to the wall section. For example, if the outer diameter is 50 mm and the wall thickness is 4.5 mm, then 50/4.5 = 11.1. This is what the SDR of the product is equal to.

Types of pipes

There are several classifications of such products. All of them are made from polyethylene (PE), but differ from each other in composition, structure and technical characteristics. For example, there are differences between PE and HDPE pipes. The abbreviation PE refers to any product made of polyethylene. But there are different production technologies:

- Made from high-density polyethylene (abbreviated LDPE) - the indicator can reach 300 MPa, and the temperature can reach 260 degrees.

- Made from low-density polyethylene (designation HDPE) - in more gentle conditions: pressure up to 2 MPa, temperature up to 150 degrees.

- Cross-linked (PE-X) - in this case, the fibers are connected both in series and in the transverse direction. Thanks to this, the product becomes even more durable.

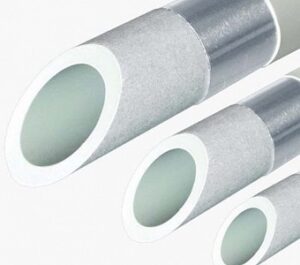

Another important classification is related to composition and structure - all pipes are divided into 2 large classes:

- Solid (consist only of polyethylene).

- Reinforced (have an insert).

An insert refers to a layer of another material that increases strength and resistance to high temperatures. It can be used as:

- aluminum (in the form of foil);

- fiberglass;

- composite based on fiber fiber and polypropylene.

Finally, PE pipes themselves are also grouped into several categories:

- PPH - used only in cold water supply.

- PPB - used for hot water supply and in the heating circuit.

- PPRC - made of copolymer, used in engineering communications, and is particularly durable.

Advantages and disadvantages

The considered characteristics allow us to highlight the following advantages of polyethylene pipes:

- completely resistant to corrosion;

- resistant to stains;

- durable (20-30 years);

- very light, easy to transport;

- simple installation;

- affordable;

- sold in long length coils, which reduces the number of connections;

- non-toxic.

At the same time, one should keep in mind the disadvantages of polyethylene pipes:

- may suffer from a cut;

- not resistant to UV radiation from the sun;

- expand greatly when heated;

- limited use in heating systems.

Thanks to these advantages, polyethylene pipes have a fairly wide range of applications. However, if the water heats up by more than 80-90 degrees, it is not recommended to use them, since deformation will be noticeable over time. Thus, the products are optimally suited for cold water supply, irrigation and water heated floors.