Device for vertical drilling: how to choose a device?

A device for vertical drilling is a special design that allows you to hold the drill strictly perpendicular to the working surface. You can purchase it in a store or make it yourself using wooden or metal sheets. The structure of this tool, the main characteristics and manufacturing stages are described in this material.

The content of the article

How the device works

You can purchase such a device or assemble it yourself. This is a fairly simple design, which consists of vertical posts. They are made of several fragments that are connected with screws. The lower element rests on the table and acts as a support.

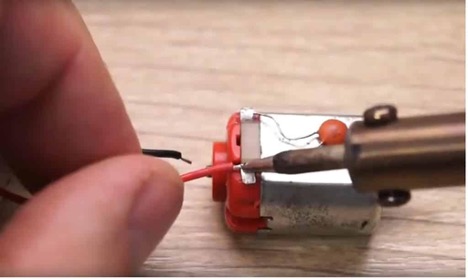

It is attached to a surface, such as a workbench, using screws. The supporting platform is equipped with a cylindrical rod. This is a stand that ensures a perpendicular position with respect to the table. The device for vertical drilling with a drill has equipment in the upper part with which the movable bracket is fixed.

It has clamping flanges that secure the drill to the surface. The design is also equipped with a drive handle. It is used to move the bracket up or down. Additional components may include a vice and devices for limiting the drilling depth.

Device characteristics

A vertical guide for a drill is a fairly simple device, which is characterized by 2 parameters:

- working length – the maximum distance over which the bracket moves;

- flange diameter.

The diameter is of particular importance because the length of the drill is related to it. In standard cases it ranges from 45 to 65 mm. But you can additionally use adapters. With their help, the flange is expanded, making it possible to use a drill with a neck diameter of both standard and large sizes.

How to do it yourself

The device is produced by different manufacturers, but you can also make it yourself. The guide for drilling is made from wooden blanks or 10 mm metal sheets. The assembly sequence is as follows:

- Secure the support to the stand of the bed.

- Use screws to secure the stand to the base.

- Install guides on it (these can be devices for furniture).

- On the moving parts of the guides, install a carriage on which to place a mount for fixing the tool.

The mechanism for moving the device for vertical drilling is assembled from a handle, as well as a spring, which returns the carriage along with the tool to its original position.

A device for perpendicular drilling can be quite useful in both professional and everyday work. However, it should not be considered as a “panacea”. In fact, you still need to hold the drill vertically with your hands while drilling. But thanks to the guide, sideways vibrations will be minimized.