Centrifugal pump: device, operating principle and technical characteristics

Centrifugal pumps – a type of pump, device for pumping water/gas. Centrifugal pumps are one of the most popular types of pumps. Due to their high efficiency, they are used in areas such as agriculture, water supply, food processing, heating and manufacturing. Centrifugal pumps supply water to a house/apartment, they are used for heating with coolant, organize irrigation of the household, and drain basements. They are also used by utility companies and first responders. Centrifugal pumps are used to pump water from wells, wells, and springs.

In this article we will understand how a centrifugal pump works, what is the operating principle of centrifugal pumps, the classification and types of centrifugal pumps, and their characteristics.

The content of the article

Design, device and features of a centrifugal pump

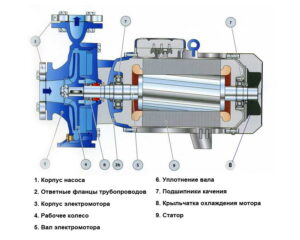

A standard centrifugal pump consists of:

- Housings

- Electric motor/motor

- Vala

- Units with bearings

- Sealant

- Impeller

- Blades

- Liquid intake pipe

- Liquid drainage pipe

The body of a centrifugal pump is shaped like a snail. The motor is covered with a protective casing for tightness and safety - it protects the working mechanism from dust and moisture.The shaft connects the motor to the impeller. Blades are installed on the wheel, which move and push the gas/liquid out of the working chamber. The wheel with blades resembles a regular fan. Bearings stand between the shaft and the wheel - they are needed to facilitate rotation. The seal is needed to protect the internal elements of the pump.

The latest models are equipped with a check valve, a filter for primary water purification, vacuum gauges, pressure gauges, regulators, and locking mechanisms.

Operating principle of a centrifugal pump

The operation of such pumps is based on centrifugal force. The process of pumping water goes as follows:

Water enters the system through the water intake pipe. The intake pipe itself is parallel to the center of the impeller. When the work area is completely filled, the electric motor turns on. It rotates a shaft, which in turn rotates a wheel with blades. The blades move water, creating centrifugal force and excess pressure. Because of this, the source water is sucked out of the pipe, and comes out of the outlet pipe with increased pressure and pressure.

Types of centrifugal pumps. Characteristics of different types of centrifugal pump

There are many types of centrifugal pumps depending on various factors. Structurally there are:

- Single stage. One impeller, low outlet water pressure. Used for small household needs, in systems with low pressure or to pump thick liquid.

- Multi-stage. Two or more discs with blades that push water out under greater pressure and pressure than single-stage ones.

By type of installation, centrifugal pumps are:

- Horizontal.

- Vertical.

Number of pipes for water intake:

- One.

- Some.

Based on pressure and power, the following models are distinguished:

- With low pressure/power – they maintain pressure up to two atmospheres.

- With average pressure/power - from two to six atmospheres.

- With high pressure/power - over six atmospheres.

By blade rotation speed:

- Low-speed equipment.

- Medium speed.

- High speed.

Centrifugal pumps can also be distinguished by the material from which the housing is made:

- Steel. Classic models are used in everyday life, in production, in industrial areas, for water supply.

- Cast iron. They are used in the same place as steel ones, but are less common. Designed to work under harsh conditions - low/negative temperatures, high humidity, dusty air.

- Copper (from copper alloys). Household models.

- Ceramic. Used to work with chemically active elements/substances.

Classification of centrifugal pumps by production method:

- Casting finished molds.

- Stamping of assembled elements.

- Riveting.

The first two types of pumps can withstand high pressure, so they are used in industry/manufacturing and central heating systems.

Types of blade pumps:

- Smooth.

- Curved (they are curved behind the side of rotation or in the opposite direction).

Centrifugal pumps are classified according to their purpose:

- Classic, pumping liquids.

- Sewer.

- Drainage

- Pumping water from wells/sources.

Characteristics of surface and submersible centrifugal pumps

Surface models are placed above the ground - on the ground near a tank, reservoir, well, borehole or other container with water. Superficial the location has its advantages - they are easy to install and repair.The disadvantages are low power and performance, compared to submersible units, they draw liquid from a depth of up to 10 meters, and often break when running dry.

Submersible devices installed inside the source - in a well, a well, a reservoir, a reservoir. The device is fixed with a cable, to which the pump clings and is pulled out if necessary. Submersible pumps are more sealed, reliable and better assembled. They are distinguished by high power and productivity - they pump water from a depth of up to 30 meters, dispense water under high pressure with a maximum pressure of 60 meters. The disadvantage of submersible centrifugal pumps is that they are difficult to repair and cannot be installed everywhere.