Scroll compressor: operating principle and device diagram (photo)

Read on and find out what a scroll compressor is, where scroll compressors are used, how a scroll compressor works, features of scroll compressors, their design.

The content of the article

Scroll compressor - what is it. Where are they used?

Scroll compressors are a type of compressor (devices that compress and accumulate air for later use). The working compression elements are two springs. One of them is mobile, the second is static. Scroll compressors are used in refrigeration equipment to ensure stable circulation of refrigerant inside the device.

This type of compressor began to be actively used in the production of refrigeration devices at the end of the 20th century, at the beginning of the 2000s.

Today they are installed in heat pumps, refrigerators, chillers, split systems and other cooling equipment.

How do scroll compressors work?

The operating principle of standard scroll compressors is as follows:

There are two springs inside a sealed housing. One of them is stationary, the second is connected to the electric motor shaft. A fan or pump pumps air, gas, refrigerant, or other liquid to the springs. The springs themselves are placed so that sealed sections are formed between them. Air/liquid fills such a section, after which the electric motor turns on.It moves the spring so as to move the sealed section with air further along the spiral. So portions of air move along the spirals to their center. Gradually along the way the air pressure increases, in the center it is maximum. A gas/liquid exhaust pipe is connected to the center, through which compressed refrigerant or air passes. It gets into the supercharger, where it accumulates. The gas then goes to the condenser. Further - depending on the needs of the equipment.

Scroll compressors are highly efficient. This is due to the peculiarities of their operation - the gas is compressed gradually as it moves along the spiral. Unlike piston or screw compressors, there are many gas contact points. This increases the durability of the equipment and its service life.

Scroll compressors, operating features. Design of scroll compressors

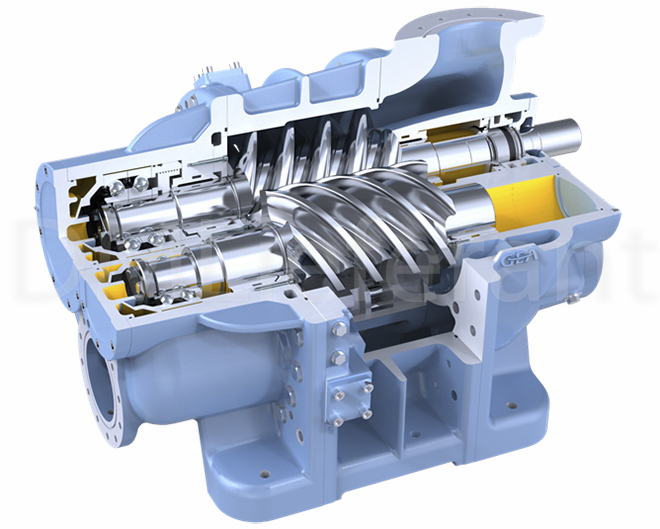

Each scroll compressor consists of:

- Electric motor.

- Vala.

- A spiral connected to the motor shaft (movable spiral).

- Fence tubes.

- Outlet pipes.

- Oldham couplings.

- Bearings.

- Check valve.

- Pressure switch/boxes with terminals.

- Cases.

- Fixed spiral.

The main difference between scroll compressors is that they have a minimum number of contacting parts, therefore there is less friction force and less oil used than their analogues. Because of this and because of the durability, reliability, and efficiency of scroll compressors, they are used in almost every refrigeration unit.

Another feature of such devices is efficiency. Here everything is explained by the fact that the engine spends less energy than in the same piston and rotary engines. As it moves in the spiral, the gas pressure and the temperature of its vapor increase, and a new portion of gas fills the newly formed section.This uniform distribution and the difference in pressure and temperature help to rotate the spiral. Thanks to this, the engine saves energy.

You can regulate the speed of steam compression in the apparatus by increasing or decreasing the number of shaft revolutions. That is, the more the shaft rotates, the faster the spring pumps and compresses the gas; the less, the slower. In the latest models, you can also adjust the volume/distance between the springs - the amount of gas compressed at a time. If necessary, you can run such a scroll compressor dry.