Removable thermal insulation of shut-off valves and flange connections: how to make

Thermal insulation of shut-off valves and flange connections plays an important role in ensuring the efficiency of heating systems and pipelines. It helps to retain heat inside the system, prevent losses and ensure reliable operation of the equipment. In this article, we'll look at not only the need for insulation, but also how to create it, including quick-release solutions, and steps to help you properly insulate for a comfortable environment and save energy.

The content of the article

Why is thermal insulation necessary for shut-off valves?

Thermal insulation of valves and removable thermal insulation are an integral part of the efficient functioning of heating systems and pipelines. These two aspects of thermal insulation are important for several reasons.

First of all, thermal insulation of valves is necessary to minimize heat loss. Shut-off valves, such as gate valves, can be a cold bridge in the system through which heat can be lost to the environment. This leads to unnecessary energy consumption and increased heating costs. Thermal insulation of valves creates a thermal barrier that retains heat inside the pipeline, providing more efficient and economical heating.

Removable thermal insulation ensures ease of maintenance and adjustment of shut-off valves. It allows you to quickly remove and install insulation if adjustment or repair work is necessary. This greatly simplifies access to the valves and minimizes system downtime. Thus, thermal insulation of valves and removable thermal insulation not only reduce energy losses, but also make system maintenance more efficient and convenient.

Basic methods of insulating gate valves

There are several basic methods of insulating gates and valves to ensure effective heat retention in the system:

- Insulating shells involve covering valves and valves with insulating materials, such as mineral wool or special thermal insulation films. These materials provide good thermal insulation and prevent heat loss through the fittings.

- Removable insulation allows you to quickly remove and install thermal insulation when access to valves and valves is necessary. This is convenient for servicing and adjusting equipment. Removable thermal insulation can be made using rivets, Velcro or other means of fixation.

- Some gate valves can be equipped with special thermal insulation coatings that are applied to the surface of the valve. These covers provide an additional level of insulation and can be easily replaced if necessary.

The choice of insulation method depends on the specific operating conditions and equipment requirements. Regardless of the method chosen, properly insulating gates and valves is an important aspect of ensuring efficient heating systems and piping.

Quick release insulation: easy maintenance

Quick-release insulation is an innovative solution that brings significant convenience to the maintenance of heating systems and pipelines. It is particularly useful in the context of removable pipe insulation where access to fittings may be necessary for adjustment, repair or inspection.

The main advantage of quick release insulation is its ease of removal and installation. Special clamps and fasteners allow you to quickly remove the insulation to access the shut-off valves, and then re-secure it in place. This significantly reduces the time spent on maintenance and saves resources. Due to their ease of maintenance, quick-release insulation becomes an indispensable element in maintaining the efficiency of heating and heating systems.

Steps to create removable insulation

Creating removable thermal insulation for insulating fittings and flange connections can be divided into several key steps:

- The first step is to select a suitable insulation material. This may include mineral wool, insulating films, special shells or other materials that provide good thermal insulation.

- It is necessary to measure the dimensions of fittings and flange connections to accurately determine the volume of insulating material required. Then it is cut and prepared for installation.

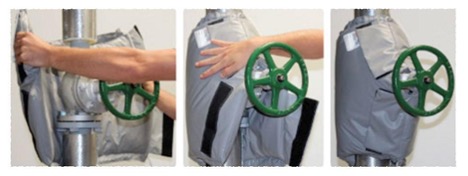

- Clamps and fastenings are installed on fittings and flanges. They serve to secure removable insulation and provide the ability to quickly remove and install it.

- Insulating material is placed around the fittings and flange connections, ensuring reliable heat retention within the system. The material should be evenly distributed and tightly secured using clamps.

- After installing the insulation, you need to check its correctness and make sure that all connections are tight. If necessary, adjustments and modifications are carried out.

These steps provide effective and convenient removable thermal insulation for insulating fittings and flange connections, which helps maintain optimal conditions in the heating system and piping and makes equipment easier to maintain.

The benefits of properly executed thermal insulation

Properly installed thermal insulation in valve and flange systems brings many benefits that play an important role in ensuring the efficiency and reliability of piping and heating systems.

Firstly, thermal insulation allows you to minimize heat loss in the system. This helps reduce heating costs and improve energy efficiency. In addition, reducing heat loss helps maintain optimal temperature inside the system, which is especially important in cold climates.

Secondly, properly installed thermal insulation helps prevent condensation and corrosion on the surface of valves and flange connections. This increases the service life of the equipment and reduces the risk of emergency situations. Thus, thermal insulation helps maintain the reliability and durability of the system.

In general, properly executed thermal insulation is an important element for ensuring the efficiency, economy and reliability of heating systems and pipelines.