Receiver for a compressor: choose or make it yourself?

How to bleed your car or industrial pump so that it pumps twice or even three times faster? Or here’s another: how to get rid of rust in a car pump? These questions often appear not only on the Internet, but also in real everyday life.

You bought a compressor and have been using it for a year or two. And then his cylinder stopped pumping air: the wall was broken and the entire air mass escapes not through the pipes, but simply into the atmosphere. No amount of electrical tape will help.

In our article we will look in detail at the “panacea” for such a problem - an additional receiver for the compressor: how to choose it and whether it can be done with your own hands. Let's begin!

The content of the article

Receiver for a compressor - what is it?

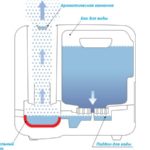

We will not go into details of the structure of the equipment, but will tell you simply and clearly - this is a container (sealed) that holds air in the compressor and stabilizes the pressure in the air pumping system. The receiver is not a mandatory equipment, but a “nice addition” to the existing system. But practice shows that such an addition as a receiver in a compressor is necessary in professional production and in everyday life. And why - read on.

One of the main tasks of the receiver is to remove condensate from air under pressure. Thanks to this, the effect of corrosion on the internal walls and tubes of the pump is reduced. The list of device functions does not end there.

Pressurized air collection

The performance of one pump may not be enough when you use several air tools at once. With a storage device, you will have enough air to spare.

Reducing the time between pump cycles

In automatic mode, the compressor turns on when the parameter decreases and turns off when the recommended pressure is reached. Traditionally, this difference is always 2 Bar. What are these 2 Bars? Blow out the part a couple of times with an air gun.

By using a receiver, the pump on/off intervals increase, and we spend less electricity and the output of our device.

Eliminating pulsations in the pump tank

Piston compressors do not supply air smoothly, but in pulses. Sometimes this causes inconvenience, but you don’t understand how to get rid of it. So, an additional air accumulator solves the problem once and for all - the pulsation effect disappears.

Now, we need to think, how to choose a compressor receiver for your situation? We will talk about this in the next subtopic of the article.

Where to look to get a good air collector (receiver) for an industrial pump

You have already become familiar with what a receiver is and what tasks it happily performs for our compressor. All that remains is to install it correctly or make it yourself.

In addition to the materials, we suggest familiarizing yourself with all the basic characteristics that air collectors need:

- Volume. For household models and industry, the cylinder indicator is different.We start from 5 liters and up to several thousand (if you have a large production). Also keep in mind that the more powerful your pumping unit is, the more powerful the receiver it needs. How to calculate: the volume of the supplement should be between a third and half of the capacity of the compressor itself.

- Operating pressure. For a household receiver, this figure does not reach 10 Bar. Commercial and industrial pumps require an air trap of 16 bar or greater. This is at your discretion and work needs.

- Bandwidth. The parameter means: how much air the receiver can push through itself in 1 minute. The more compressed air you need for your job, the higher capacity you look for in the shop.

That's all. Such a small list of parameters helps determine whether you purchased the right air collector. And, of course, avoid critical mistakes and overpaying for unnecessary equipment.

Homemade receiver for a compressor: how to make it yourself

There is a list of jobs that require high air flow under pressure. But conventional compressors may not be able to cope with this. One of the options to get out of the situation is to create a receiver for the compressor. You can do this yourself with a minimum set of knowledge.

Why is it better to make an additional receiver for a compressor? It's simple: a steep price. Based on the volume of the device, the cost of such an accessory starts from 10 thousand rubles or more. In addition, store-bought receivers are designed for standard pumps - they may simply not be suitable for certain models

How to choose a receiver for a compressor: you can connect it either independently or to the main one. The last option is easier.

For the base, use a gas cylinder or a simple fire extinguisher.The container is cleaned of the remnants of the products that were in it. Afterwards, the inlet valve is removed (only with hand tools - there is a high probability of a pop from residual gas).

The resulting container is filled with water and sits for more than a day - it sours. Then, pipes under the hoses are welded into the cylinder. The tank is coated with corrosion-resistant paint.

If you need to install additional nozzles (condensate drain or pressure gauge), then we make additional threaded connections.

The finished installation is placed on a steel stand or tripod. You need to use the model like this:

- A steam trap is required.

- Before loading, check the compressor itself for its ability to work with the receiver’s calculations. To do this, turn on the pump on empty, and use a flow meter to check the difference when turned on (you need to do the procedure for about 20 minutes). If the pressure does not fluctuate or drop to the recommended value, then you can pump air with the receiver.

- If the pressure drops, then the continuous operation of the standard compressor is reduced (from 75 to 50 percent).

Now you know how to set up and connect an additional receiver to the compressor. If you have any questions or suggestions, feel free to ask them in the comments below. We are always happy to answer and supplement our materials!