Concrete mixer repair: we find problems and fix them ourselves

As the concrete mixer is used, it becomes contaminated with a mixture of cement and sand, and individual parts become unusable. Therefore, it is necessary to know the mechanism of the mechanism in order to correctly determine the cause. You can repair a concrete mixer yourself if you know exactly what is broken. Step-by-step instructions for the most common cases can be found in this material.

The content of the article

Causes of breakdowns

There are objective reasons for failure related to wear and tear over time. But often the mechanism breaks down in cases where the equipment is used incorrectly. For example, a concrete mixer is hindered by concrete due to excessive load. Failure to comply with storage conditions or lack of lubrication on the ring gear can cause damage. Very often, breakdowns occur due to the fact that the drum is not cleaned immediately after the end of kneading.

Before you repair a concrete mixer yourself, you need to figure out which unit is damaged:

- Gears usually break due to errors during operation. Often, owners lubricate the rings and gears, believing that this reduces the load on the engine. But in fact, as a result, it only increases. Due to lubrication, the cement-sand mixture gets caught on the teeth, so friction increases.Therefore, it is important to understand how to use a concrete mixer correctly.

- Gearbox - it wears out quickly due to overloads or insufficient cooling. This unit cannot be repaired - you only have to replace the part or the entire assembly.

- The ring gear also experiences heavy loads during operation. Most often, parts made of cast iron break, so it is better to install a plastic crown. You need to figure out how to disassemble a concrete mixer and make a proper replacement.

- Shutdown buttons - often breakdowns are associated with them. For example, when pressed, the mechanism starts normally, but after a few minutes it stops. Then you need to install a new button. It is important to know the structure of a household concrete mixer. The new button should be exactly the same in terms of the number of pins.

Once you have managed to understand the reason, you can begin to repair the device. To do this, prepare screwdrivers and other tools, remove the housing if necessary, and replace the components.

How to repair a concrete mixer

The repair depends on which part is broken. In some cases, for example, when replacing a drive, this is quite simple to do. But if you do not have the necessary skills and understanding of how a concrete mixer works, it is better to turn to specialists so as not to damage the mechanism. The main types of repair work are described below.

Drive replacement

If the drum does not rotate, and the motor operates normally, this is most likely due to a faulty belt. To correctly assess the situation, you need to remove the cover and inspect it. In this case, be sure to disconnect the contacts.

The simplest case is when the belt works, but simply slips. It is enough to return it to its place.If it is worn out, it will need replacement. They work like this:

- Remove the belt.

- Loosen the locknut.

- Remove the bolt securing the drive mechanism.

- Lift it up and unscrew the belt.

- Taking a new belt, thread it between the drive gears and lower it to the stop.

- Tighten the retaining bolt and locknut.

- Reinstall the belt.

After replacement, you need to figure out how to properly use the concrete mixer. If you work carefully and avoid unnecessary loads, the unit will last quite a long time without repairs.

Checking drive tension

If the belt is in good condition, but it is loose, then the problem is due to insufficient tension. Solving it is quite simple - to do this, proceed as follows:

- Tilt the mixer.

- Remove the belt.

- Loosen the locknut.

- Remove the bolt.

- Pull the mount with the electric motor to the required distance and secure its position with a bolt and lock nut.

- Reinstall the belt and check its tension.

Concrete mixer clogged

During operation, the unit inevitably becomes clogged with cement-sand mixture. Normally, it should be washed immediately after use, but sometimes the mixture hardens and covers the surfaces with a dense layer. To figure out how to clean a concrete mixer from hardened cement, you can use the following methods:

- Mechanical cleaning – the frozen mass is removed with a chisel or hammer, after which it is carried out with a grinder and a special brush. Smaller parts are sanded with sandpaper.

- Chemical method - use professional products, for example, “Anti-concrete”. They can also be used for prevention.

- The hydraulic method involves removing dirt using powerful water pressure.

In all cases, it is important to know the structure of the concrete mixer, especially when working with a hammer. In order not to damage the device, you need to act carefully, measuring the force of the impact. If you are not sure, it is better to use a grinder and sandpaper, and then treat the surfaces with a special concrete remover.

Bearing replacement

If you figure out how to work with a concrete mixer, the mechanism will work for a long time. But in any case, the main components wear out and therefore require replacement. For example, if the device turns normally, but does not start immediately, and the motor makes extraneous sounds and hums, the reason is probably related to the bearing.

To understand how to work with a concrete mixer correctly, during repairs proceed as follows:

- Remove the box covering the motor.

- Remove the bulb, then remove the gear.

- After this, you need to remove the locking ring, after squeezing it.

- The shaft is knocked out.

- Place a wooden board on it and knock it out, removing 2 bearings.

- Then they replace and reassemble the unit, proceeding in the reverse order.

After this, you need to start the unit again to check its operation. If the sound is standard and the movement is normal, then the cause has been corrected correctly.

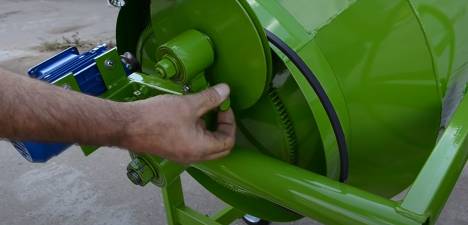

Pulley replacement

The pulley is made of plastic. In this case, the shaft on which it is put on is machined with a milling cutter on one side. Therefore, when the hole on the pulley becomes absolutely round, it begins to rotate freely. As a result, the motor and pulley rotate normally, but the shaft does not. In such cases, you should figure out how to remove the pulley from the concrete mixer. They work like this:

- Unscrew 2 nuts.

- Remove 2 bolts (they secure the box to the frame).

- Remove the box and the pulley.

- Unclench and remove the retaining ring.

- As a result, the pulley falls out on its own.

- Then a replacement is made and the unit is reassembled using the reverse algorithm.

Thus, repairing the unit is not so difficult. It is necessary to determine the cause, and then understand how to remove the barrel from the concrete mixer, remove the pulley or replace the bearings. If you are not sure, it is better to seek additional advice from professionals.