Membrane bioreactor for wastewater treatment: operating principle

One of the advanced methods of wastewater treatment is the use of a membrane bioreactor. This technology combines biological treatment with membrane filtration. It provides a high level of contaminant removal. A bioreactor is not just equipment, it is a complex system that can adapt to various conditions and cleaning requirements.

The effectiveness of membrane bioreactors for wastewater treatment is based on their ability to simultaneously perform biological treatment and membrane filtration. This not only removes organic contaminants, but can also significantly reduce the content of harmful substances in your purified water. This makes the water reusable.

The content of the article

A little history

Membrane bioreactor (MBR) technology began to develop rapidly in the 1960s. It was then that the idea of combining biological treatment with membrane filtration to increase the efficiency of wastewater treatment was first proposed. However, widespread adoption and commercial application of this technology began in the 1980s. This was due to significant progress in the development and production of membranes. This was also made possible by improving the characteristics of membranes. They are valued for the following characteristics:

- strength;

- selectivity;

- durability;

- reducing their cost.

All this has made MBRs more accessible for widespread use in wastewater treatment systems.

The development of membrane bioreactors has stimulated research and innovation in water treatment technologies. This has led to the development of more efficient and cost-effective treatment systems. Since then, ICBMs have undergone significant changes, including the following:

- improving reactor design;

- optimization of membrane operation;

- implementation of automated process control systems.

Modern membrane bioreactors are the result of years of research and development, offering a highly efficient solution for wastewater treatment with minimal environmental impact.

The principle of operation of a bioreactor: from theory to practice

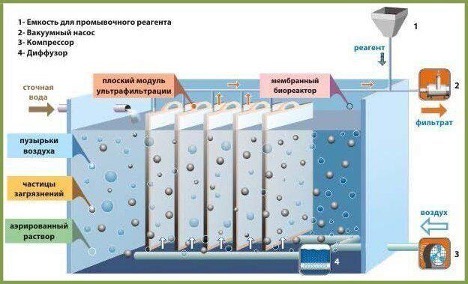

The operating principle of the bioreactor is a complex process that combines biological treatment and membrane filtration. The basis of the technology is the use of microorganisms to decompose organic pollutants contained in wastewater. These microorganisms living in activated sludge absorb and process pollutants, thereby purifying the water.

For the system to operate effectively, certain conditions must be maintained, such as temperature, pH, oxygen and nutrient concentrations. These parameters influence the activity and growth of microorganisms, which, in turn, determines the degree of wastewater treatment. Membrane bioreactors for wastewater treatment are equipped with modern systems for monitoring and regulating these conditions, which allows optimizing the treatment process and increasing its efficiency.

The membrane module in the bioreactor plays a key role in purification. The membranes serve as a barrier to bacteria, viruses and other large particles, preventing them from entering the purified water.Depending on the type of membrane, varying degrees of purification can be achieved, including the removal of salts and organic molecules.

However, to maintain high productivity and efficiency of a membrane bioreactor, regular maintenance and cleaning of the membranes is necessary. Contamination of membranes can lead to a decrease in membrane throughput and, as a result, increased operating costs.

Key system components and their functions:

- microorganisms that decompose organic pollutants, purifying water at a biological level;

- membranes that filter purified water, removing microorganisms and large particles;

- a control system that regulates process conditions (temperature, pH, oxygen), optimizing the functioning of microorganisms.

Features and benefits

The use of a membrane bioreactor in wastewater treatment plants has a number of undeniable advantages:

- High degree of water purification from organic substances and microorganisms.

- Minimal environmental impact thanks to closed processing system.

- Possibility of reusing purified water in various fields.

The main components of the system, such as a laboratory bioreactor, allow for constant monitoring and optimization of the purification process. This approach provides not only efficiency, but also economic benefits from using this technology.

Innovations and development prospects

Despite all the advantages, developers continue to improve the technology of membrane bioreactors. One of the directions is integration with the so-called “peat engine”.This is an innovative system that allows you to further increase cleaning efficiency through the use of natural absorbents.

The introduction of new technologies and materials opens up new horizons for improving the quality and availability of wastewater treatment. Scientists regularly use improved membranes and dietary supplements. This not only improves the environment, but also provides additional opportunities for recycling and use of water resources.

In conclusion, it can be argued that a membrane bioreactor is a promising and effective solution for wastewater treatment that meets modern environmental and technological requirements. The development and implementation of this technology plays a key role in ensuring sustainable development and protecting natural resources.