Mechanized plaster and what it is: characteristics of the application method

We can say about mechanized plaster that it is a modern way of applying the composition using a special apparatus. Thanks to the use of equipment, the speed of work increases by 4-5 times, and the quality is practically guaranteed. These and other advantages, as well as instructions for applying the composition, are described in detail in the presented article.

The content of the article

Advantages and disadvantages

It is enough to simply understand what mechanized plaster is. This is a special way of applying the composition - not manually, but using special equipment. Moreover, mixtures that are worked with without tools are not suitable for these purposes. The mechanized method of applying plaster involves the use of 2 types of compositions:

- gypsum;

- cement-sand.

Essentially, these are universal mixtures that can be worked with manually. And thanks to the use of application equipment, they have other advantages:

- significant time savings - work can be completed 5 times faster;

- excellent adhesion strength to the surface;

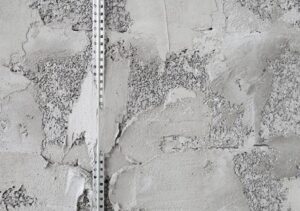

- uniform distribution ensures the solidity of the layer;

- even thick layers (up to 70 mm) can be applied in one go, saving time and effort;

- the walls are obtained without cracks;

- For such types of work a 1-2 year guarantee is provided.

But mechanical plastering of walls also has its disadvantages.As such, this method is indeed more effective than traditional manual technology, but is more expensive since a special apparatus is required. At the same time, it is not necessary to buy it - you can rent it or invite a team of craftsmen, which is also affordable.

How to lay mechanized plaster

In terms of preparatory work, the mechanical method of applying plaster is not much different from the classical one. But the main stage has its own characteristics. The step-by-step instructions are as follows:

- Prime the wall to improve adhesion. The work is done with a regular roller.

- In order to lay the plaster efficiently, measurements are taken with a laser level and metal beacons are installed.

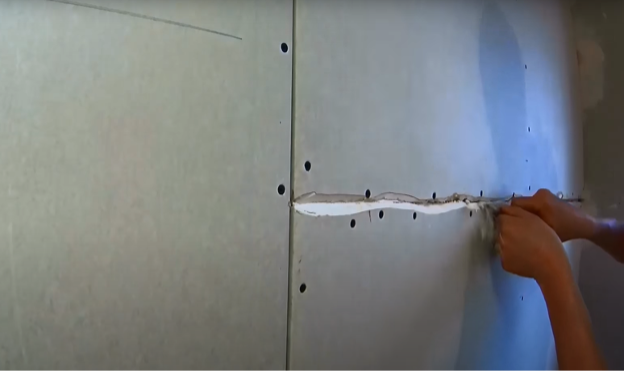

- Next they move on to reinforcing the joints - this increases strength. The work is carried out using fiberglass mesh, the material of which must be resistant to alkalis.

- Now all that remains is to knead the mixture and apply it using the machine. This is done at high speed to uniformly fill all differences and irregularities.

- Align by beacons using a rule.

- While the composition is not dry, remove the beacons (otherwise they will rust). After them, seams remain, which are covered with the same composition, but by hand. Then make the surface level using the rule.

- Rub the surface with a sponge grater dipped in water. The milk that appears is puttied and the wall is prepared for painting or wallpaper.

- All that remains is to let the composition dry completely. To do this, open the windows a little to avoid strong drafts and sudden temperature changes.

The use of mechanized plaster allows you to achieve a perfectly smooth surface.The process is noticeably faster - even large areas in a house or apartment can be processed in a matter of hours. However, it is worth remembering that not all compositions are suitable for the mechanized application method. Therefore, you should buy only suitable mixtures based on gypsum or cement with sand.