Compressor "Remeza": operating instructions and tips from experienced

Next you will learn what a compressor is and what its purpose is, the technical characteristics of the Remeza compressor, the design of the Remeza compressor, how the Remez compressor works, how to use the Remeza compressor, what care is needed for the Remez compressor, what not to do with the compressor, how to transport and store the Remeza compressor.

The content of the article

- Compressor - what is it, what is its purpose?

- Technical characteristics of the Remeza compressor

- How the Remeza compressor works inside

- Operating instructions for the Remeza compressor

- The compressor automatically switches off the engine at maximum pressure

- How to care for the Remeza compressor

- Rules for transportation and storage of the compressor from Remez

- It is recommended to lift the equipment as low as possible from the floor

Compressor - what is it, what is its purpose?

Compressors – devices for compressing and storing air for subsequent use in pneumatic technology. Compressors produce compressed air, which is used in pneumatic devices, tools, and equipment.

Remez compressors are used in industry, car services and everyday life. Standard compressor sets do not include filters to clean the air from moisture, oil and solid microelements. Only professional and specialized compressors are equipped with them in order to obtain a higher class of compressed air purity.

Technical characteristics of the Remeza compressor

Compression ratio – 2.

Cylinders, quantity – 4 pcs.

The volume of the oil tank is 2 liters.

Oil consumption to compress a cubic meter of air is 0.02-0.03 grams.

Suction, performance - depends on the model, from 1000 to 1700 liters per minute.

The volume of the receiver is 5 hundred liters.

Power – depends on the model, from 7.5 to 11 kilowatts.

Dimensions – 200 by 61.5 by 125 centimeters (length by width by height).

Weight – depends on the model, from 340 to 385 kilograms.

The number of engine hours before overhaul is 7.5 thousand.

How the Remeza compressor works inside

The main components of Remeza compressors:

- Working block, pistons.

- Motor/electric motor.

- Belt.

- Receiver.

- Housing/protective cover.

- Pressure gauge.

- Check valve.

- Safety valve.

- Condensate drainage system.

- Receiver tap.

- Bed/base.

- Compressor feet/wheels.

- Shock absorbers on legs.

- Automation.

- Control panel or pressure switch with switch.

Operating instructions for the Remeza compressor

The first thing after receiving the compressor is to unpack it - lift the device, remove the pallet, remove the packaging and seals.

Next, install the unit on the shock absorbers in a pre-designated location. Check the device for malfunctions/damage:

Carefully inspect the electrical cable - it must be intact and without damage. Also make sure the pipeline is intact. At this stage, check the documents and characteristics of the device, everything should match. If necessary, tighten the mounting bolts.

First start:

- Wipe the compressor with a dry cloth.

- Pour oil into the system, you need to fill 2 liters.

- Open the air outlet valve on the receiver.

- Connect the device to the mains.

- Press the power button on the control panel.

- Wait a few minutes until the oil is distributed throughout the entire system and the mechanism warms up.The receiver tap is open.

- Close the outlet valve.

- Wait until the receiver is completely filled, the pressure rises to the maximum level.

- Reduce pressure. Release air from the system - connect pneumatic equipment or open the receiver tap.

The compressor automatically switches off the engine at maximum pressure

Subsequent times of turning on the Remeza compressor:

- Inspect the device for damage/malfunctions.

- Wipe the device with a dry cloth.

- Connect pneumatic equipment.

- Plug the compressor into the outlet.

- Click the "Auto" button on the panel.

- Wait until the receiver is full and use compressed air.

To turn off the compressor:

- Press the power button on the panel.

- Reduce pressure and bleed air from the system.

- Remove the plug from the outlet.

How to care for the Remeza compressor

To extend the life of your device, you should daily:

- Check, monitor and adjust the oil level in the oil tank and system.

- Inspect the compressor for external faults.

- Drain condensate from the system.

- Clean/wash equipment from dust and dirt.

- Check the tightness of bolts and nuts at the end of each working day.

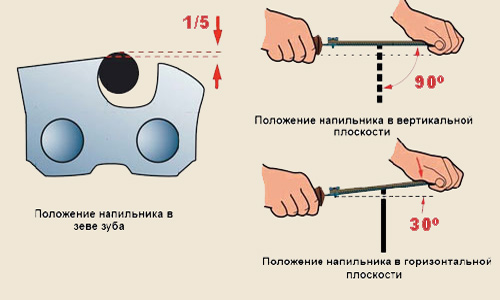

We recommend checking the tightness of the bolts in the piston block, in particular the cylinder head bolts, every week/50 working hours, as well as checking the tension of the drive belt and its integrity.

Every two/four weeks you need to change the oil in the block, check its integrity, and, if necessary, clean or replace the primary coarse filter.

Once every three months, change the oil, check the tension of the belt drive, as well as the fastening of the frame with working elements to the receiver.

Once every six months it is necessary to change the coarse air filter. The check valve should be checked and serviced every year.

What you must not do with the compressor:

Use without grounding, incorrectly connected compressor or without electrical protection.

Operate during precipitation – during snow/rain – without coating/protection. Install the compressor in an explosive area. Start the compressor without shock absorbers rigidly attached to the floor.

Rules for transportation and storage of the compressor from Remez

To transport a compressor from Remez:

- Disconnect the device from the power supply and the blower.

- Reduce the pressure inside the receiver - it should be at atmospheric level.

- Secure wires, hoses, pipes and other loose items.

- Using specialized tools, lift the compressor.

- Place the unit on a pallet, in packaging or in a shipping container.

It is recommended to lift the equipment as low as possible from the floor

The compressor can be transported only in closed means - in covered bodies/trailers of trucks or cars, train cars, containers. When transporting your compressor, follow standard safety precautions and regulations based on the labeling of your equipment.

Remez compressors can be stored in packaging, covered on a pallet or in a container. The device must be stored indoors - the compressor must not be exposed to snow, rain or other environmental conditions. The air must be clean - free of large contaminants and not dusty. Its relative humidity should not exceed 80%, so as not to damage the unit. Remez compressors can be stored at temperatures from -25 degrees Celsius to +50 degrees Celsius.