Expanded clay as sound insulation: what is it for, its properties and characteristics

The properties of expanded clay allow it to be used as a heat-insulating material. The granules are small and porous, so they protect well from the cold. Although you need to take into account that they absorb water well, so you need to take care of waterproofing. The main characteristics, pros and cons of the material are discussed in the presented article.

The content of the article

Composition and production technology

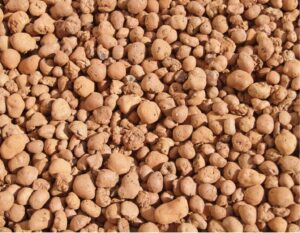

Expanded clay is a porous building material that is produced using the technology of firing natural clay. Moreover, they do this in rotary kilns at high temperatures (in the range of 1100-1200 degrees). The result is grains of different fractions with a diameter from 5 to 40 mm, mostly oval in shape.

The composition of expanded clay is represented by the following substances:

- silicon oxide in the form of silica 70%;

- aluminum oxide 12%;

- iron in the form of various oxides 10%;

- organic impurities up to 8%.

The properties and characteristics of expanded clay are related to the technology of its production. There are 2 main ways to get it:

- Wet (plastic or slip) - the clay is sent to 2 stages of grinding using a coarse and fine roller. After obtaining round granules with a diameter of up to 10 mm, they are dried in a rotating drum. It is then fired at high temperatures and left to cool.

- To soundproof the floor with expanded clay, material prepared by the dry method is also used.The raw materials are crushed to grains of a certain fraction and immediately sent for firing in a drum without preliminary drying. Because of this, the result is not round granules, but grains with angular outlines.

Areas of application of expanded clay

What expanded clay is needed for is almost always related to the construction industry. The material is used as insulation for various structures:

- Insulation of floors - a vapor barrier film is laid on the slab and expanded clay granules are covered on top. They do the same with a wooden floor, but boards are also laid on top of the granules. Thanks to this, not only protection from the cold is provided, but also from rodents.

- Sound insulation with expanded clay is used at the stage of wall construction. You can make masonry in 3 layers - a load-bearing structure, expanded clay mixed with cement “milk” for the middle layer and a protective layer.

- Expanded clay material is also used as insulation for the attic. To do this, prepare an empty space, lay lathing in it, lay a vapor barrier film and fill the voids with granules.

Thus, the quality of expanded clay allows it to be used as insulation. The material provides heat and sound insulation, which is especially important for urban houses. But you need to take into account that porous granules absorb moisture well. Therefore, when laying, be sure to use a vapor barrier - a film made of dense materials that do not allow water to pass through.

Expanded clay fractions

Sound insulation with expanded clay, as well as its use as insulation, is justified if you know the basic properties of the material. First of all, you need to familiarize yourself with the size of the fractions - according to this indicator, 4 groups are distinguished:

- From 0 to 5 mm - this is expanded clay sand, which is used for floor screed, as part of heat-insulating plaster and in masonry mortar.

- From 5 to 10 mm – fine expanded clay is used for arranging heated floors.

- From 10 to 20 mm - expanded clay gravel, the characteristics of which allow it to be used as a universal material. Allows you to insulate all building elements - ceiling, floor, walls, roof.

- From 20 to 40 mm is the largest fraction. It is used in cases where maximum thermal insulation is needed, for example, during the construction of a foundation, when insulating an attic floor, cellar or basement. Such expanded clay is also used as sound insulation.

Main characteristics

If you study what can be made from expanded clay, you need to pay attention to its characteristics:

- Strength – measured in MPa. The indicator is especially important when using material for backfilling the floor. Strength directly depends on porosity and is designated by grade from P15 to P400.

- The hygroscopicity of expanded clay is high - this means that the material absorbs a large amount of moisture. That is why during installation it is necessary to make a high-quality vapor barrier.

- Bulk density in kg/m3 - the higher this indicator, the stronger the coating, although the worse the thermal insulation properties. Density range – from 100 to 1000 kg/m3. It is best to choose average values of 400-500 kg/m3.

- Thermal conductivity is the most important characteristic, which depends on humidity, bulk density and granule size. The lower the humidity, the lower the bulk density and the larger the granule size, the greater the ability to retain heat. If these conditions are not met, the disadvantages of expanded clay will appear to a greater extent than its advantages.The indicator is determined by the coefficient of thermal conductivity - the optimal value is from 0.07 to 0.16 W/(m*K).

- The compaction of expanded clay provides strength, but no less important is the frost resistance indicator, which is measured by the number of cycles. The minimum should be 15 cycles, although today the material can withstand 25 to 50 cycles.

- To soundproof a floor, expanded clay must be of high quality and safe. Therefore, you should pay attention to the radioactivity indicator. According to the standard, it should not be more than 370 Bq/kg.

Advantages and disadvantages

Considering the properties of the material and comparing it with others, for example, what is the difference between shungizite and expanded clay, we can highlight several advantages of granules:

- Good thermal insulation - every 10 cm corresponds to 100 cm of brickwork or 25 cm of wood covering.

- Can be laid on any base, for example, just on the ground, concrete or wood.

- The material is non-flammable, which ensures fire safety.

- It lasts for several decades - with proper installation and use of waterproofing, at least 40 years.

- Natural composition, absence of harmful impurities.

- You can pour it into spaces of any shape, you can do the installation yourself.

- Resistant to fungi, bacteria and other microorganisms.

- The granules are dense and durable, so they can also be used for floor insulation.

But there are also disadvantages:

- It absorbs moisture well, so it needs very good waterproofing.

- The soundproofing properties of expanded clay are not so pronounced, so it is used mainly for protection from the cold.

- For good thermal insulation, you need to fill a high layer, which can reduce the height of the room.

- The material is quite dusty, you need to work in a respirator, use gloves and special clothing.

Expanded clay remains one of the most popular insulation materials. It is especially often used when backfilling a floor, basement or cellar, i.e. in those places where you can make a large layer. At the same time, analogues, for example, polystyrene foam, are often used for walls. Therefore, before making a decision, you should calculate the thermal insulation depending on the climatic conditions of the area and the quality of the walls, roofing and other floors.