Frame-fill walls of a house: what kind of material is it, pros and cons

A frame-fill house is a structure with multi-layer walls. Insulation is poured between the outer and inner sides. Previously, sawdust was used for this; today, mineral wool, polyurethane foam and other artificial materials are more often used. The features, pros and cons of such a house are described in the presented article.

The content of the article

Home arrangement

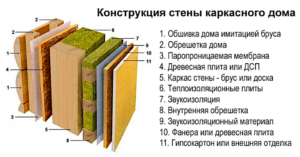

The basis of such a structure is frame-fill walls - this is a structure that consists of several layers. They may be different, but 3 elements are fundamental:

- outer wall;

- interior wall;

- insulation.

Moreover, in reality there are many more layers. These are external and internal cladding, external and external sheathing, heat and sound insulation, as shown in the diagram.

Sawdust is often used as insulation, which is literally poured between the outer and inner walls. That is why the name “frame-and-fill house” appeared. Artificial materials with excellent thermal insulation can also serve as filler:

- ecowool;

- polyurethane foam;

- fiberglass;

- expanded polystyrene (regular or extruded).

Frame-and-fill houses always have outer cladding, which is made of several materials:

- imitation timber;

- block house;

- lining;

- plywood with moisture-resistant properties;

- façade panels;

- shingles;

- Chipboard and others.

The same materials are used for the interior lining.Along with them, gypsum plasterboard and gypsum plasterboard are sometimes used. Such sheets are suitable for interior finishing, but they are not suitable for external cladding.

Types of frame houses

The pros and cons of frame-fill houses should be considered in connection with the features of the specific technology of their construction. In practice, there are 2 types most often found:

- Finnish.

- Canadian.

In approximately 80% of cases, Finnish infill houses are built in Russia. The distinctive properties of the design are:

- The frame is made of timber. It is collected directly at the construction site or at the factory.

- This frame is already sheathed on the outside and inside, which makes installation easier.

- Fiberglass and mineral wool are used as insulation. Modern generation materials are also used - polyurethane foam and ecowool.

The pros and cons of an infill house using Canadian technology are also related to construction technology:

- It is made from multilayer panels - sandwiches. Such structures consist of wooden beams, and insulation (polyurethane foam or polystyrene) is immediately placed in them. Pressure is applied to the material using a press to obtain maximum density. Next, the external and internal cladding materials (plywood with moisture-resistant properties, chipboard, metal or others) are glued on.

- The material of the walls of a frame-fill house is timber. A rigid frame is made from it, ensuring structural strength. Since the walls are already ready, installation occurs very quickly.

The design can be not only one-, but also two-story. In such cases, there are 2 more types of frame-fill houses with their pros and cons:

- With floor elements, when they make 2 separate frames and place them on top of each other. This is a platform construction scheme.

- With one frame that goes to both floors. This is a two-story or end-to-end scheme.

Pros and cons of a frame house

Now it’s clear what a frame-and-fill house means. The structure consists of 2 walls, between which there is space - insulation is placed in them. Despite the existence of different construction technologies, such houses remain very popular:

- One of the main advantages is the price. A frame-and-fill house will cost about 30% less than a log or beam. And if compared with brick - by 50%.

- The pace of construction is very high. Even if a small team of 3 people is working, you can put the structure on the foundation in literally 3-4 weeks. If you work with ready-made kits, you can assemble them in just a few days.

- There is no need to involve heavy equipment, which allows you to save on costs.

- Such houses are energy efficient, the walls provide minimal heat loss, so structures can be erected even in regions with frosty winters.

- You can start finishing and creating communication networks already during the installation of the walls.

- A frame-and-fill house is a structure that can be erected at any time of the year, regardless of weather conditions.

But this design also has disadvantages:

- Fire Hazard – Almost all materials used during construction are flammable.

- Wooden walls are susceptible to rotting. But if you choose high-quality materials, process them correctly, install vapor barriers and ventilation, they will last for several decades without any complaints.

- Sound insulation is not the highest, so if the house is near a road, you should consider using additional materials.

- One of the short-lived options is a sawdust mound house.The insulation is quite good, but it gradually sags, so it is necessary to regularly top it up to restore the volume. In addition, sawdust is prone to rotting and needs to be treated with antiseptics.

A frame-and-fill house is convenient in terms of ease of construction and low cost of work and materials. But it is important not to skimp on quality and strictly adhere to installation technology. To erect the structure, it is better to involve a team of professionals with many years of experience in such work.