How to connect asbestos pipes to each other and how to cut them: installation and fastening

Connecting asbestos-cement pipes and their installation is an important step in the construction and repair of communication systems. This process requires special attention and adherence to technology to ensure durability and reliability of the connections. In this article we will look at how to connect asbestos pipes together, as well as methods for cutting and installing them.

The content of the article

Features of asbestos-cement pipes

Asbestos-cement pipes are a unique building material that combines the strength of asbestos and the stability of cement. These pipes are widely used in construction for water supply and sewerage systems. They are also used in various communication and industrial systems. The main advantage of asbestos-cement pipes is their high strength and durability. This allows them to be used under high loads and aggressive environments.

In addition, asbestos-cement pipes have good chemical resistance. This makes them suitable for transporting various types of liquids, including weakly acidic and alkaline solutions. This feature makes them an ideal choice for applications in the chemical industry and wastewater treatment systems. Also, asbestos-cement pipes are not subject to corrosion. This property significantly extends their service life compared to metal counterparts.

An equally important feature of asbestos-cement pipes is their environmental friendliness and safety for the environment. Despite the presence of asbestos in the composition, modern production technologies provide a high degree of protection against the release of asbestos fibers into the environment. This makes them safe both for installation and for use in various conditions. Thus, asbestos-cement pipes are a reliable and safe material for the construction of modern engineering systems.

Preparing for connection

Before you begin joining asbestos pipes, it is important to carefully prepare for this process to ensure the reliability and durability of the connection. Preparation includes several key steps. It all starts with choosing the right materials. And it ends with the immediate preparation of pipes for installation. The first step is to carefully inspect the pipes for damage and defects, since even minor cracks or chips can significantly reduce the strength of the connection.

An important part of the preparation is the following list of necessary tools and materials:

- hand saw for metal or diamond blade for cutting asbestos-cement pipes;

- rubber O-rings or special couplings for connection;

- lubricant to facilitate installation of o-rings;

- protective equipment for working with asbestos materials, including a respirator and safety glasses.

Once everything is ready, it's time to trim the pipes so that they fit together well in size and angle. Here it is important to be careful and precise so that the parts fit perfectly.When cutting, make sure everything is done correctly and safely to avoid damaging the pipes and to ensure smooth and clean cuts. After cutting, you need to remove all dust and asbestos residues so that it is safe for health.

The preparation ends by applying lubricant to the sealing elements, such as rings or couplings. This will help connect the pipes easily and make the connection waterproof. It is important to distribute the lubricant evenly, avoiding excess amounts, so that the connection is of high quality. After this, the pipes will be ready for installation, which must be done in compliance with all rules and standards.

Cutting asbestos-cement pipes

In order to cut an asbestos-cement pipe, you can use several tools: a hand saw for metal, a diamond blade on a grinding machine, or a specialized machine for cutting asbestos-cement. It is important to follow safety precautions when working, such as using a respirator and safety glasses, as asbestos dust is released when cutting.

Installation of asbestos-cement pipes

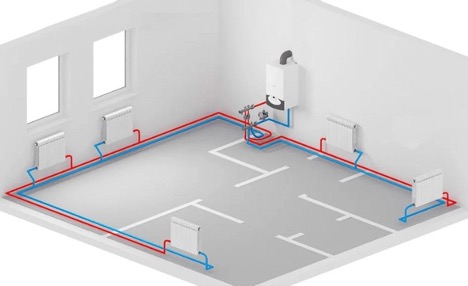

The process begins with preparing a pit or trench and laying the underlying layer. It is important to provide the correct slope and a reliable base for the pipes to avoid their deformation and destruction.

Various methods are used to connect asbestos-cement pipes to each other:

- end connection using rubber O-rings;

- coupling connection using special asbestos-cement or plastic couplings.

The following steps will ensure a reliable connection:

- Checking the compatibility of connected parts.

- Apply lubricant to O-rings to facilitate installation.

- Carefully connecting the parts and checking the tightness of the fit.

Transition from asbestos pipe to plastic

Often during the installation process it becomes necessary to switch from asbestos pipes to plastic ones. For this purpose, special adapters or transition couplings are used to reliably connect pipes of different materials. It is important to choose high-quality fitting products that match the diameters and operating conditions of the system.

Errors during operation

At each of these stages, errors can occur that lead to a decrease in the quality of work and even the need for rework. Here is a list of the most common mistakes when working with asbestos-cement pipes:

- Working with asbestos-cement pipes requires the use of personal protective equipment, such as respirators and safety glasses, to avoid inhaling asbestos dust.

- Using improper cutting tools or improper technique can result in uneven edges, making it difficult to join the pipes.

- Pipes that are not cleared of dust and dirt can reduce the quality of the connection and lead to leaks.

- Using unsuitable couplings, seals or lubricants may result in an unreliable connection.

- Not checking connections for leaks after installation is a common mistake that can lead to leaks.

- During installation, it is necessary to take into account the thermal expansion of asbestos-cement pipes, otherwise this may lead to deformation or damage to the connections.

- Installing pipes with cracks or other damage can lead to rapid system failure.

Storing asbestos-cement pipes in unsuitable conditions can lead to their damage even before installation begins. And this also needs to be taken into account.

Conclusion

Thus, connecting asbestos-cement pipes and cutting them require careful preparation and adherence to technological processes. Correct installation of asbestos-cement pipes and careful execution of all stages of work will ensure the durability and reliability of communication systems. It is important to remember safety measures when working with asbestos-containing materials and, if it is necessary to switch from an asbestos pipe to a plastic one, use high-quality connecting elements.