How and with what to weld a copper pipe: welding copper with stainless steel

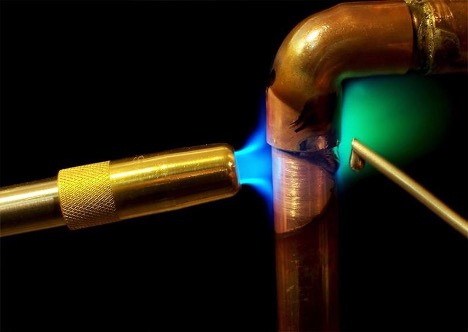

Welding copper pipes requires certain knowledge and skills. First of all, it is important to choose the appropriate method and materials. How to weld copper pipes is a question that requires an understanding of the characteristics of copper as a material. Copper is a soft metal, so not all technologies are suitable for welding it. The best choice would be to use TIG welding or soldering.

Before starting work, it is necessary to carefully prepare the surfaces of the pipes. Clean them from dirt, degrease and polish until shiny. This will ensure better adhesion of the materials being welded. In addition, it is important to accurately select welding parameters, including power and feed rate of welding material, to avoid overheating and damage to the pipes.

The content of the article

What is TIG welding

TIG welding (Tungsten Inert Gas), also known as argon arc welding, is a type of arc welding method that uses a non-consumable tungsten electrode. The main difference between TIG welding and other types of welding is the use of an inert gas, most often argon, to protect the welding zone from the external environment. This method produces a clean, high-quality weld, making it ideal for working with thin and high-alloy metals such as stainless steel, aluminum and, of course, copper.

The advantage of TIG welding is high precision and control over the welding process.The welder can adjust the intensity of the arc and the amount of material fed, which provides excellent control and allows the creation of thin, neat welds without excess material. This welding method is also characterized by no spatter and minimal welding fumes, making the process cleaner and safer. Due to these characteristics, TIG welding is widely used in the aviation industry, shipbuilding, as well as in the manufacture of complex metal structures and artistic products.

Welding copper with stainless steel

Welding copper with stainless steel is a process that requires special attention. Combining these two metals can be difficult due to differences in their physical properties. For example, copper and stainless steel have different thermal conductivity and coefficient of thermal expansion. To successfully weld, you will need to choose the appropriate welding method and material.

One effective method is the use of TIG welding using special filler materials that can connect copper to stainless steel. It is necessary to ensure constant temperature control during the welding process to prevent the formation of cracks and other defects at the junction of metals. It is also important to carefully prepare the surfaces to be welded, ensuring they are clean and properly aligned.

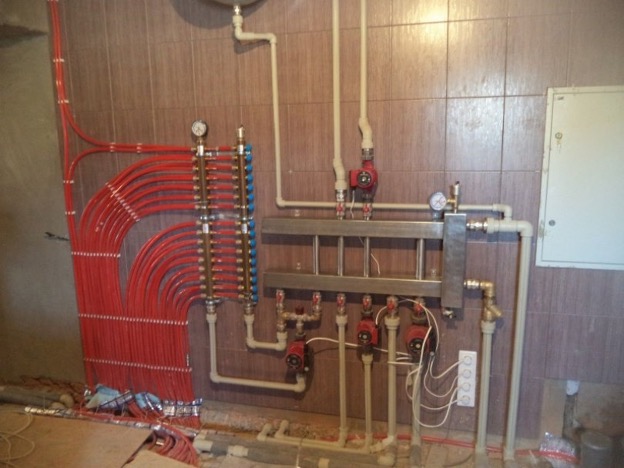

How to weld a copper pipe

The choice of material for welding copper pipes plays a key role in the quality and reliability of the connection. How to weld a copper pipe? Depending on the welding method you use, select the appropriate welding material:

- When TIG welding, use filler material based on copper-nickel alloys or special electrodes.

- Special copper-phosphorus or silver solders are suitable for soldering.

When choosing a material, take into account the temperature regime, the characteristics of the metals being connected and the operating conditions of the finished structure. High-quality material will ensure the strength of the connection and its durability.

Copper electrode welding

This is one of the methods for joining copper pipes. The method is suitable for work where high precision and quality of the weld are required. Copper electrodes have good electrical and thermal conductivity, allowing precise control of the welding process.

When using copper electrodes, it is important to maintain a stable voltage and current to ensure even heat distribution and prevent overheating of the metal. It is also necessary to ensure good ventilation of the workplace, as gases may be released during welding.

How to cook copper pipes

The process of welding copper pipes requires compliance with certain technical conditions. How to weld copper pipes is a question whose importance cannot be underestimated. Welding copper requires care and control to avoid overheating and deformation of the material.

First, choose the correct welding mode based on the thickness of the copper pipe and the type of welding equipment. Secondly, use proper safety equipment such as a welding helmet and gloves to ensure safety while working. Finally, after welding is complete, thoroughly clean and inspect the weld for any defects.

conclusions

In conclusion, how to weld copper pipes is a process that requires careful attention to detail and safety precautions. Welding instructions and recommendations must be strictly followed to ensure long lasting and reliable connections.Remember that the quality of the weld directly affects the strength and safety of the entire structure.