Automation for a well pump: all the advantages and disadvantages

We have prepared material for you about automation for a well pump. In this article, you will learn what automation is for a well pump, what is considered automatic for a well pump, the operating principle of automatic well pumps, how safety automation for a well pump works, what are the advantages and disadvantages of automatic well pumps.

The content of the article

What is automation of a well pump? What is considered automatic for a well pump? What functions does automation perform for a well pump?

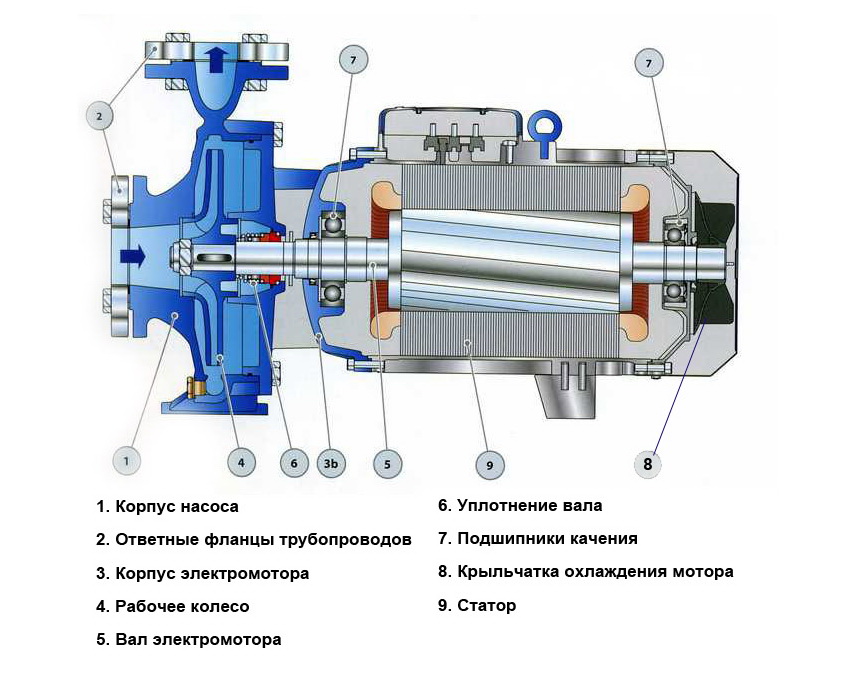

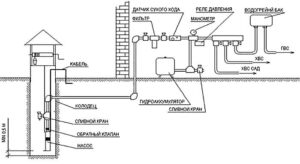

Well pump automation – a set of electrical devices on pumps. These include a pressure switch, dry-running protection, overheating/overload protection, power surges, and leaks. Indirectly, automation can be called a pressure gauge, thanks to which the user knows what pressure is in the pipeline and can regulate the operation of the pump.

Automation functions for the pump:

- Control and automatic operation.

- Protection.

A set of these devices allows you to better control and regulate the operation of the electric pump.Also, the system of these devices ensures automatic operation of the pump - the mechanism automatically turns off when the line is filled with water and the pressure reaches the required level. The pump shut-off pressure level can be adjusted using a pressure switch. You can control the speed of rotation of the motor.

The automation protects both the line itself and the pump. When water fills the pipeline and the required pressure rises, the relay turns off the motor so that the water supply does not suffer a water hammer. Automation creates a supply of water, thereby extending the service life of the pump. This is also convenient during a power outage - there is a supply of water at home. Automation protects the pump from dry running - when there is no water in the chamber, and the motor rotates the impeller with blades. To do this, there is a mechanism inside that starts when there is no water - it opens the contacts, and electricity does not reach the motor.

How automation for a well pump works. Well pump protection mechanisms

The pump automation works mechanically - by measuring the physical parameters of water in the liquid supply and discharge pipes. For example, a pressure switch: the main structural elements are a housing, two springs/pistons, adjustment nuts, a flange, a membrane, clamps for contacts. The water pipe is connected to the pressure switch through a flange. It contains a flexible membrane. The pump pumps water into the main line, the pressure increases, and the water puts quite a lot of pressure on the membrane. It puts pressure on the pistons/springs, which open the contacts, and electricity does not reach the motor - the pump stops.

A hydraulic accumulator can indirectly be considered an automation of a well pump, so we will also tell you its operating principle. It is a cylinder with a membrane inside.The membrane separates the empty part of the cylinder from the filled part with air. Air is pumped into it at the factory. Water is poured into the empty space. When there is a lot of it, it puts pressure on the membrane, compressing the air. Once you open the tap, air will push water out. This increases the pressure in the system.

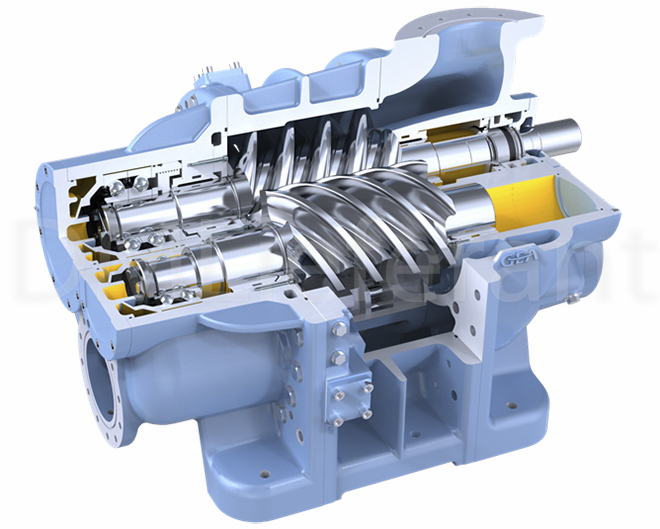

Modern borehole pumps are made in one piece - in them the control unit, motor, pump housing and hydraulic accumulator are connected into one unit. This is necessary so that the pump fits into narrow wells.

The operating principle of the downhole pump's protective automation is based on turning off the power. Control mechanisms/sensors associated with radio components are installed in the pump. When the mechanism/sensor gives a signal, the radio components open the contacts and electricity does not reach the motor. For example, dry running protection:

The pump has a mechanism or water sensor. When it does not give a signal, the device opens the power circuit.

Protection against overloads and unstable power consists of a fuse system. When too much current is supplied to the pump, the fuses take the blow.

Pros and cons of automatic well pump

Let’s say right away that there are no downsides to an automatic pump. If your pump is equipped with automation, there are only advantages. Your device operates automatically, turns itself on and off, and has surge protection. If the pump begins to leak inside the housing, the protective system will turn off the power and notify the user of the leak with an LED indicator or an audible signal.

The only downside is that some devices do not work correctly/incorrectly, in particular digital ones and sensors.